A machining company is much more than a parts supplier: at Asimer Group it means having a strategic partner that integrates machining production, specialized welding and engineering solutions for critical components of pumps and valves.

In industries such as Oil & Gas, cryogenics, naval, water treatment and desalination, precision and on-time delivery determine plant continuity. Choosing well is not just a technical decision: it’s a business decision.

At Asimer Group we are a machining company that combines technical expertise, innovation, and commitment to deadlines.

Why choose a machining company for your industry?

- Repeatability batch to batch thanks to CNC/CAM and dedicated fixtures.

- 100% traceability per part via ERP (routes, inspections, versions, and releases).

- Committed OTD and milestone visibility to meet deadlines.

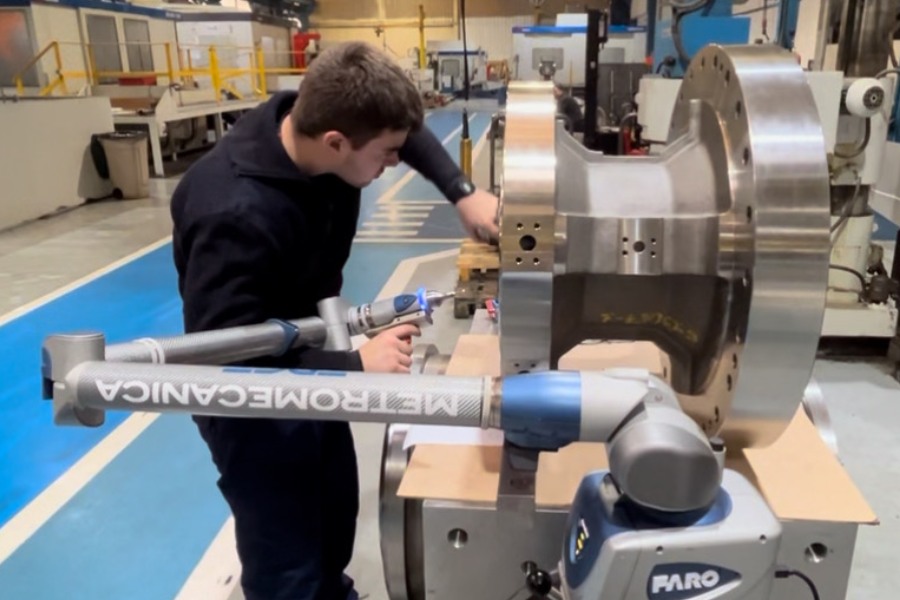

- Advanced metrology: ~20 °C room, 3D arm/CMM and 100% inspection on criticals.

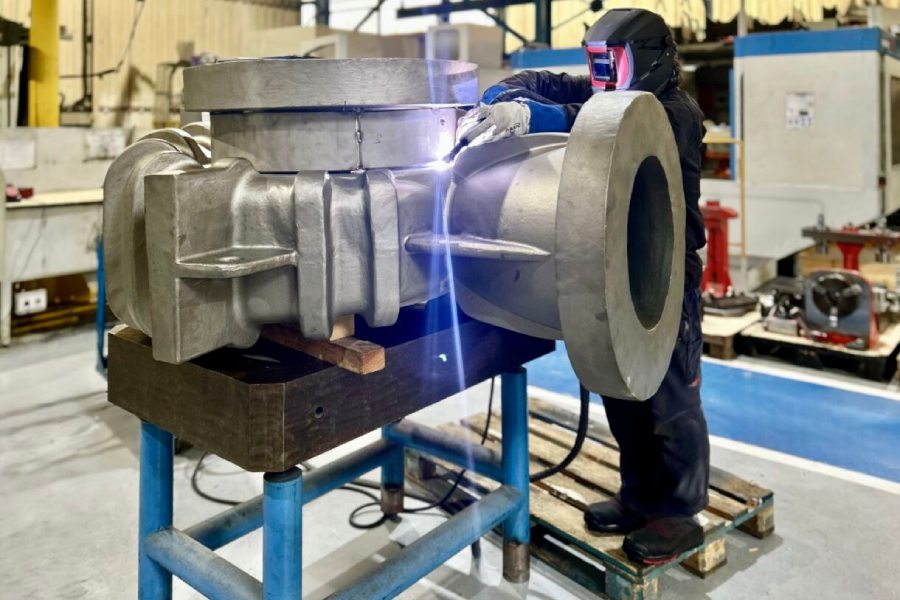

- Certified welding TIG/MIG/MAG and PTA (ASME IX, UNE-EN ISO 3834-2).

A reliable machining company does not just “cut chips”; it delivers process. We combine technology capacity, manufacturing criteria and start-up processes with metrology control to deliver parts that are repeatable, traceable, and ready for service.

We work with multi-axis centers, CNC lathes and vertical lathes, documenting every phase to reduce risks and shorten approvals.

See our machinery catalog.

Contact our team and tell us about your machining or welding project.

We will reply within 48–72 h with a tailored proposal.

Asimer Group services as a machining company

Based on customer drawings and specifications, we machine industrial stainless steel parts. We deliver machined parts of complex geometry with repeatability and traceability in every batch.

- Key capacities: Trevisan machining centers (DS900/600/500/300/200), CNC lathes and vertical lathes, milling/boring (Zayer, Sacem, Tos Varnsdorf).

- Processes and control: repeatable CNC machining for demanding industrial processes; CAM optimization, rigid fixturing, and thermal stability.

- Common materials: stainless steels, SuperDuplex, Inconel®, Hastelloy®.

- Documentation and quality: 100% dimensional control on criticals, measurement reports, NDT when required and traceability per part via ERP.

This range of capabilities consolidates us as a reference machining company in Spain.

With CNC technology geared to production, our CNC machining applications rely on CNC machining tools of high performance to reduce variability and cycle times.

CNC precision machining in critical components

We machine bodies, covers, impellers, and shafts for pumps and valves (including large format). When required, we achieve accuracy in CNC machining with tolerances of ±0.01 mm and finishes up to Ra 0.2 µm, ensuring functional fit (coaxiality, concentricity) and tightness.

Depending on geometry and material, we combine chip removal machining with turning and boring strategies. To sustain that precision, we combine rigid clamping, thermal stability, CAM optimization, and dedicated tools for SuperDuplex, Inconel® or Hastelloy®.

We have Trevisan centers (DS900, DS600, DS500, DS300, DS200), vertical lathes and milling/boring capacities (Zayer, Sacem, Tos Varnsdorf); thus, we handle large parts with repeatability and stability. The Trevisan machining center provides rigidity and productivity in large format. In addition, we are specialists in large-dimension valve machining.

TIG, MIG/MAG Automatic and PTA (Hardfacing) Welding

We use TIG, MIG, Automatic MIG and PTA for overlays that reinforce critical areas exposed to wear or corrosion. These processes allow us to recover seats, seals, or shafts with precision. After welding, we machine to final dimension and verify flatness, circularity, and tightness according to drawing and inspection plan. The result: longer service life and lower total cost compared to manufacturing a new part.

TIG welding is used in operations where controlling heat and penetration is essential, such as fine overlays or joints that will later be machined to tight tolerances.

The choice between TIG and MIG depends on geometry and tolerances. The differences between TIG and MIG welding determine the level of heat input and the risk of distortion. In demanding overlays, we apply Plasma Transferred Arc (PTA) welding, which deposits wear- and corrosion-resistant alloys with precise dilution control, before final machining.

Advanced Metrology and Dimensional Control

Quality is built during the process, not at the end. We perform 100% dimensional control on critical diameters with high-precision probes and sensors, complemented by inspections with a 3D measuring arm and CMM. In our metrology room, we maintain a controlled temperature of ~20 °C to ensure measurement stability. When required, we apply non-destructive testing such as penetrant testing (PT), visual inspection (VT), or ultrasonic testing (UT), delivering measurement reports with full traceability linked to ERP.

Our Metrology Room integrates calibrated measuring instruments and applies types of non-destructive testing such as penetrant liquids when needed.

Sectors Where a Machining Company Makes the Difference

Each sector presents critical challenges where a machining company delivers added value through precision and reliability.

We work with industrial valves and pumps in demanding environments, adapting materials and controls depending on the sector.

Oil & Gas and Petrochemical

Components exposed to severe pressure and corrosion require robust processes: we apply corrosion-resistant overlays, followed by final machining and non-destructive testing to ensure tightness per ITP/tests and a low rework rate. Our expertise in high-accuracy machining for the Oil & Gas sector enables us to handle the most critical components of valves and pumps, including the machining of fittings in the oil and gas industry, which require tight tolerances and coatings to withstand severe conditions. We also work in petrochemical and offer machining and welding outsourcing in the Oil & Gas industry. In oil refining operations, dimensional control and NDTs reduce reprocessing.

Water Treatment and Desalination

We machine and weld valve bodies and bonnets, as well as pump casings and covers in stainless steels and superalloys exposed to saline environments and suspended solids. Precision in flanges and sealing surfaces prevents leaks and improves energy efficiency.

When a centrifugal pump operates with solids or salinity, we machine seats and flanges to ensure tightness and integrity of the assembly.

Our expertise in machining stainless steel valves and pumps guarantees reliable finishes in sealing surfaces exposed to highly corrosive environments.

Naval and Defense

We machine and weld shafts, bonnets, and bodies of valves and pumps for naval environments, where resistance to vibrations and marine corrosion is essential. We ensure tight tolerances and complete documentation, collaborating with OEMs and industrial partners to meet specifications and deadlines.

Cryogenics

In cryogenic applications, we machine and weld bodies, bonnets, casings, and impellers in special materials. These parts, subjected to extremely low temperatures, require micron-level tolerances, control of thermal contraction, and specific tightness tests.

Tell us your sector-specific need.

We will provide a tailored proposal for your application.

Asimer Group’s Key Differentiators

KPIs That Matter: OTD, Quality in Criticals, and Lead Time

OTD (On-Time Delivery) is a priority KPI in our daily operations. We plan with buffers, manage bottlenecks, and provide milestone visibility to meet committed deadlines. We also track KPIs for quality in critical dimensions (PPM in key diameters) and lead time according to complexity and workload.

Industry 4.0, Traceability, and Documentation

Our machining processes are interconnected with the ERP system to achieve part-by-part traceability (routes, inspections, drawing versions, and releases). This visibility reduces risks and shortens approval cycles. We integrate Industry 4.0 to monitor milestones and ensure real-time traceability.

Flexibility: Prototypes, Short Runs, and Large Volumes

From single-unit parts to repeatable batches, we adapt tooling, cutting strategies, and controls to optimize total cost without losing precision. We deliver customized solutions when geometry or service requires it. We handle machining of small vs large series in industrial pumps and also in valves, maintaining repeatability and control in both cases to reduce costs and increase precision.

Sustainability and Total Cost

The combination of PTA overlays and precision machining allows us to recover and extend the service life of critical components, instead of replacing them with new parts. This way we reduce waste, lower material consumption, and optimize the total cost of ownership while supporting carbon footprint reduction in industrial pumps and valves.

Comparison: Standard Supplier vs. Specialized Machining Company

The difference between a standard supplier and a specialized machining company like Asimer Group is clear.

| Aspect | Standard Supplier | Asimer Group – Machining Company |

|---|---|---|

| Precision & Finish | Variable | ±0.01 mm and up to Ra 0.2 µm with CNC precision machining |

| OTD (Deadlines) | Not managed | OTD as KPI, planning with buffers and committed deadlines |

| Documentation & Quality | Basic | Dimensional reports, non-destructive testing, and traceability per project |

| Demanding Materials | Limited scope | Broad experience in stainless steels, SuperDuplex, Inconel®, Hastelloy®, and others |

| Metrology | Final inspection | 100% control in criticals, climate-controlled metrology room, and checks with measuring arm & CMM |

| Approach | Execution to drawing | Technical partner delivering machining production, process engineering, and innovation |

Success Stories: Machining and Welding in Real Environments

Butterfly Valve Bodies Top Entry 24” 300# BW

For a German customer specialized in Oil & Gas and LNG, Asimer Group completed 8 butterfly valve bodies Top Entry 24” 300# BW.

Project scope:

- CNC pre-machining.

- Intermediate inspection with liquid penetrant testing (PT, Level II).

- Final machining.

- Final tests: PT, VT, and PMI.

Technical highlight: Triple-offset butterfly valves employ a conical geometry with three offsets, eliminating friction at closure and ensuring tight shutoff per ITP/tests, even under high pressure, temperature, and aggressive media.

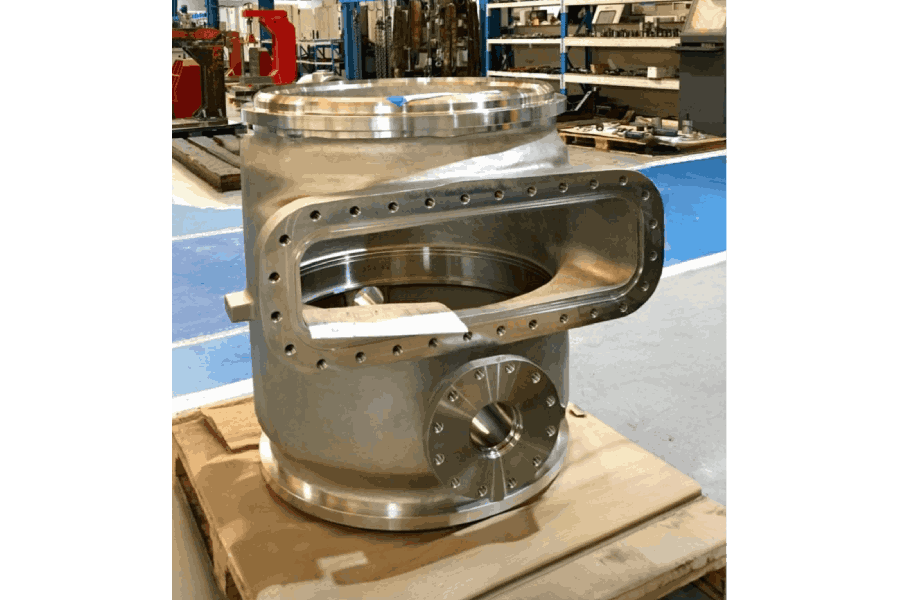

Plug Screw Feeder Housings in A316Ti (1.4581)

For a leading OEM in the pulp & paper sector, we delivered 6 housings for Plug Screw Feeders in stainless steel 1.4581 / A316Ti.

Project scope:

- Pre-machining on CNC vertical lathes.

- Intermediate non-destructive testing (PT on critical areas).

- Final machining with tight geometric tolerances.

- Final inspections: PT & VT (Level II) per ITP requirements.

Technical highlight: Plug screw feeders compress biomass (chips, sawdust, straw) into a sealed plug for transfer to preheaters or pressurized vessels, removing air, water, and resins. Optimized compression and dewatering reduce steam demand and energy consumption in downstream drying.

Key advantages:

- Longer service life under abrasive and corrosive conditions.

- Lower motor load and reduced energy consumption.

- Improved dewatering efficiency with lower process costs.

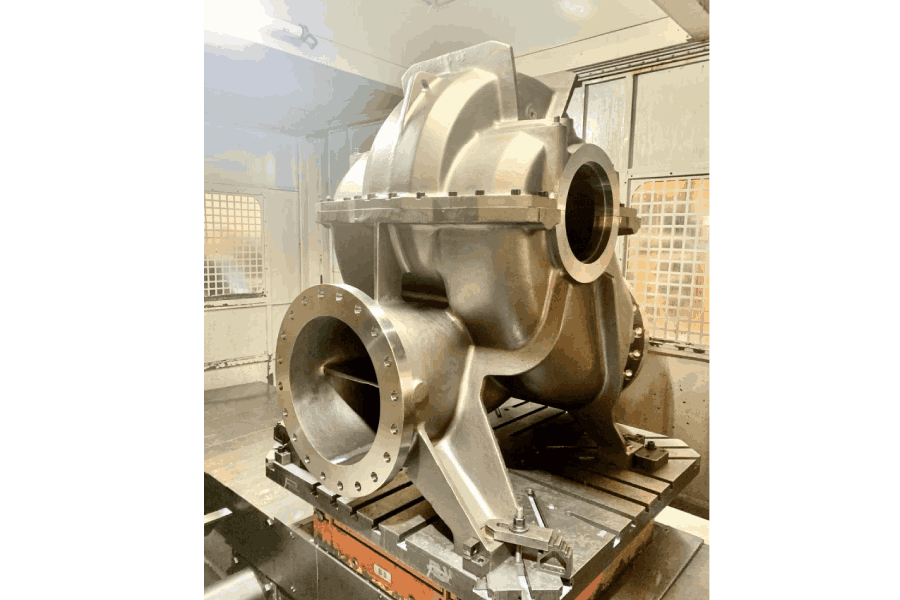

Horizontal Radially Split Pump Casings in CF3M

For a French company specialized in engineered pumps for Oil & Gas, we delivered 3 horizontal radially split pump casings, single-stage, double-suction, centerline mounted, in stainless steel CF3M. The project required special tooling and custom machining sequences.

Project scope:

- Pre-machining.

- PT inspection in sealing areas (Level II operator).

- Final machining with tolerance control.

- Final inspections: PMI, PT, and VT (Level II).

Technical highlight: These thermal oil transfer pumps handle clean, hazardous fluids at high temperatures. Their between-bearings, single-stage, radially split design ensures reliable operation in demanding process services.

Features and benefits:

- Minimum bearing clearance to reduce shaft deflection.

- Impeller with stepped vanes for low NPSHR and minimal pressure pulsations.

- Radial bearings with sleeves and tilting pad design with forced lubrication.

- Centerline mounting to allow free thermal expansion and withstand high nozzle loads.

- Casing in stainless steel or chrome-plated with excellent mechanical properties.

Application: These industrial thermal fluid pumps circulate oil through parabolic collectors for heating and subsequent transfer to the solar steam generator. They stand out for their ability to operate at high temperatures while ensuring reliability, efficiency, and long service life.

How to Choose a Reliable Machining Company

- Tolerances/Finishes: Can you guarantee ±0.01 mm and Ra 0.2 µm in my criticals?

- Materials: Proven experience with SuperDuplex / Inconel® / Hastelloy®.

- Capabilities: Do you have Trevisan machining centers and boring/milling for my range?

- KPIs: How do you manage OTD and lead time? What visibility will I have?

- Metrology: 100% control in criticals, controlled environment, and 3D arm/CMM.

- Documentation: Dimensional reports and NDTs per project.

- Traceability: ERP management with routes, inspections, and versions.

Our approach helps optimize machining costs in pumps and valves without compromising tolerances.

Certifications and Quality Assurance

We operate under ISO 9001 (quality management) and hold UNE-EN ISO 3834-2 for fusion welding. We also comply with ASME IX for welding and welder qualification in TIG, MIG/MAG, and PTA, with certified personnel in non-destructive testing (PT, VT, UT).

These foundations, together with internal controls and documentation traceability, support our deliveries in regulated sectors such as Oil & Gas, cryogenics, and naval.

If you are looking for a machining company that combines CNC precision, advanced welding, and serious metrological control, let’s talk. We integrate KPIs (OTD, critical quality, lead time) and traceability to ensure your project arrives on time and on spec.

Contact Asimer Group if you are looking for a machining company able to guarantee precision, traceability, and on-time delivery.

Contact us nowFrequently Asked Questions (FAQs)

What does a machining company like Asimer Group do?

We integrate CNC machining, welding (TIG, MIG/MAG, PTA), and metrology to manufacture or recover critical components with tight tolerances and project documentation.

What is the difference between CNC and conventional machining?

CNC machining offers repeatability, precision, and efficiency in time and cost, especially in series production, large dimensions, and demanding materials.

Which sectors do you serve?

Oil & Gas, naval, cryogenics, water treatment, desalination, and pulp & paper, among others.

How do you ensure quality?

100% control in criticals, Metrology Room (controlled environment), 3D arm/CMM, and NDTs when required. We deliver measurement reports and traceability.

What certifications do you have?

ISO 9001 and UNE-EN ISO 3834-2.