Welding and Special Overlay

Certified Quality and Innovative Processes

Discover how Asimer Group leads in specialized welding services, offering hardfacing processes and special contributions that enhance the quality of your products. Our Welding Department is committed to excellence (certified according to ISO 3834-2) and performs two key functions: repairs on cast parts (porosity or shrinkage in parts during machining processes) and special contributions (nickel base and cobalt base), providing solutions known for their surface hardness and certified quality. It is important to highlight that all welding processes are controlled with their corresponding NDT (Non-Destructive Testing), whether PT, MT, PM, and Rx, with PT Level II operators.

Welding and Special Overlay

Certified Quality and Innovative Processes

Discover how Asimer Group leads in specialized welding services, offering hardfacing processes and special contributions that enhance the quality of your products. Our Welding Department is committed to excellence (certified according to ISO 3834-2) and performs two key functions: repairs on cast parts (porosity or shrinkage in parts during machining processes) and special contributions (nickel base and cobalt base), providing solutions known for their surface hardness and certified quality. It is important to highlight that all welding processes are controlled with their corresponding NDT (Non-Destructive Testing), whether PT, MT, PM, and Rx, with PT Level II operators.

FOUNDRY REPAIRS

Steels and alloy steels

ASTM austenitic

stainless steels

Tuesdayintic steels A 743

Duplex ASTM A995

Foundry repairs

SPECIAL CONTRIBUTIONS

Cobalt base

Nickel base

Welding Services

Welding Overlay

Special Welding (Hardfacing Overlay)

Quality Certification - ISO 3834-2

Approvals and Welding Processes

Welding Processes - Innovation in Action

MIG (Metal Inert Gas): Perfect for quick and efficient joints.

TIG (Tungsten Inert Gas): Ideal for high-precision welds on delicate materials.

PTA (Plasma Transferred Arc Welding): Ideal for applications requiring high quality and durability, PTA welding combines precision and control in the fusion process.

Automatic Welding: We have automatic welding machines to guarantee precision and consistency in every joint.

Industry Experience

- Commitment to Quality: Our processes and materials meet the industry’s most demanding standards.

- On Time Delivery (OTD) represents the most important indicator in ASIMER.

- Personalized Approach: Every project is unique. We work with you to understand your needs and tailor our solutions.

Featured Projects

Welding the rings (A316L + Stellite Gr.6) inside the bodies

Globe Valve Bodies with stellite 21 hardfaced in the seat

Machining production

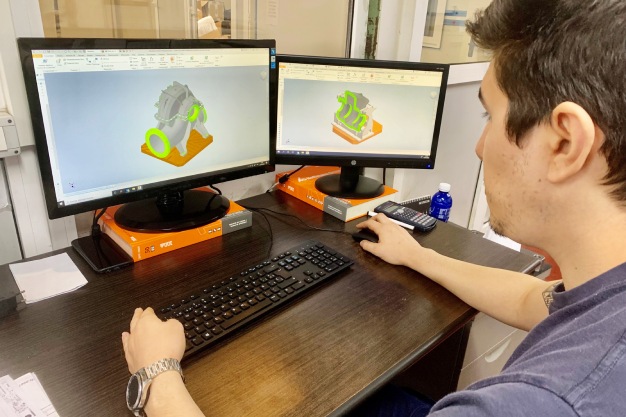

Asimer Group has the most modern technical means for Machining processes, interconnected with its Management System (AGP).

Engineering solutions

Asimer Group is specialized in project management, quality assurance (QA) and engineering through the integration of different manufacturing technologies.