What is oil refining?

Oil refining is an essential process for transforming crude oil into marketable products such as fuels, lubricants and kerosene. A typical oil refining process consists of several processing units, such as distillation, cracking, post-treatment and refining of products. The operation of these processes requires large amounts of thermal energy and results in the release of significant amounts of CO2 from different sources at the refinery.

Once crude oil is extracted from the soil, it must be transported and refined into oil products that have some value. These products must be transported to end-use consumers or retailers (such as petrol stations) The overall supply chain of oil products among consumers is segmented into three components.

- Upstream: Includes exploration of crude oil fields and crude oil production.

- Midstream: Handles the distribution of crude oil to refineries, the refining of crude oil into marketable products and the distribution of products to wholesalers and retailers.

- Downstream: Its activity is the retail sale of oil products. Petrol stations are perhaps the most visible companies in this market.

Why is oil refining important?

Oil is known as one of the most important energy sources in the world, and its refinement is essential to acquire the goods we use in our day to day. Among them, we can find gasoline, diesel, jet fuel, cooking gas, lubricants and many other products. All of these products are essential to the global economy and our modern way of life.

The refining process involves the separation of the different components of crude oil, such as hydrocarbons, sulphur and other pollutants, using techniques such as distillation, hydrodesulphurisation, hydrotreatment and catalytic reform. Moreover, the refining process is also important because it reduces the environmental impact of crude oil. Crude oil contains a large number of pollutants, such as sulphur, which can cause damage to the environment and human health. The refining process significantly reduces the amount of pollutants and therefore reduces the environmental impact of its use.

In the oil refining process, every detail counts to ensure the quality and efficiency of the final product. From extraction to distribution, industrial pumps play a critical role in moving components enriched by the refining process.

To execute this process, it is essential to have essential components such as pumps and industrial valves, which allow control the flow of the different components during the refining process. In this article, we will explain the importance of oil refining and its relation to welding and accuracy machining of industrial pumps and valves.

What role do industrial pumps and valves play in oil refining?

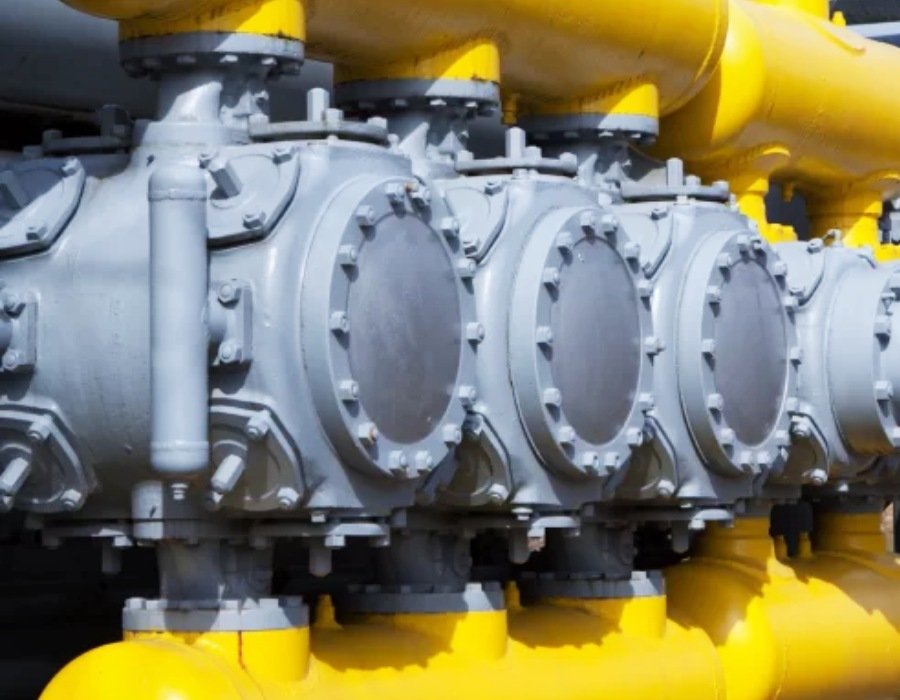

Within the oil refining process, industrial pumps and valves are essential components. Pumps are used to transfer crude oil from storage tanks to distillation towers, while valves must control the flow of different components during the refining process.

The main function of the pumps is to move crude oil from one place to another in the refining process. This is done through pipes that connect different sections of the refinery. Pumps are necessary because crude oil is very dense and viscous, making it difficult to move through the pipes. Pumps are used to make crude oil flow more easily through the pipes and thus speed up the refining process.

In contrast, valves are critical components used to manipulate the flow of various components throughout the refining process. The valves handle the amount of crude oil and the other components that flow through the pipes and distillation towers. This is crucial to ensure that the various components are combined correctly and that the refining process is completed correctly and properly. If a valve no longer works well, it could cause an interruption in the refining process, which can cause economic losses and, in extreme cases, dangerous injuries.

Therefore, it is essential to have high quality and precise industrial pumps and valves in the oil refining process. Welding and machining are key processes for manufacturing these high quality pumps and valves.

Industry 4.0 and the CNC Machining Revolution

In the current context of Industry 4.0 and the CNC Machining Revolution, the importance of petroleum refining becomes even more relevant. With the advancement of technology and automation, companies in the sector are adopting innovative solutions to optimize refining processes and improve efficiency in the production of industrial pumps and valves.

Machining and welding at Asimer Group and its relationship with the oil refining process.

Linking to the previous paragraph welding and machining are crucial processes in the manufacture of industrial pumps and valves.

Welding is essential for joining different components of pumps and valves. Industrial pumps and valves are made of different parts and materials that must be joined safely and reliably. Welding is used to attach these parts so that they are resistant and can withstand the extreme working conditions to which they are subjected.

Machining, on the other hand, is used to shape and finish the different parts of pumps and valves. Industrial pumps and valves are made of different materials, such as steel, aluminum and special alloys, and require very high precision in their manufacture. Machining is used to shape these parts and finish them so that they are compatible with the specific needs of the refinery.

Oil refining is a fundamental process for our economy and modern way of life, and its relationship with welding and machining of industrial pumps and valves is essential to ensure the quality and safety of this process.

Asimer Group, as an engineering company that integrates machining and welding services for industries focused on different sectors such as oil & gas, focuses its experience in machining casting and forging parts within the valve and industrial pump sector and in special welds of all kinds of materials. We are a key partner for the oil refining industry as we have the ability to provide customized solutions to meet the specific needs of each refiner.

In conclusion, oil refining is a complex and critical process that requires the collaboration of different industries, including the manufacture of industrial pumps and valves. The industrial pump and valve machining and welding company is a crucial partner in this process and can provide customized solutions to meet the specific needs of each refinery. Its experience in the manufacture and repair of critical parts ensures the safety and efficiency of the oil refining process.