CNC machining, or Computer Numerical Control, represents a revolution in industrial manufacturing. Instead of relying solely on manual skill, CNC machines use advanced software to control tools and machinery with extraordinary precision and consistency.

Currently, CNC is essential in industries ranging from automotive and aerospace to medicine and electronics. Its ability to produce complex components with minimal human intervention has radically transformed manufacturing processes, improving efficiency and reducing production times.

In the exciting field of metal machining through computer numerical control, CNC machining is presented as a true art form that has transformed the way we face the challenges of working with metals.

CNC Machining: A Deep Exploration of its Fundamentals

Definition of CNC Machining

CNC machining, short for Computer Numerical Control, functions as the master craftsman of machines in the manufacturing world. It uses computer programs to guide machines and production equipment, allowing astonishing precision and exceptional efficiency in creating metal parts through chip removal machining. This fluid method not only ensures precise details but also optimizes the production process admirably.

Historical Evolution of CNC Machining

To fully understand CNC machining, it is vital to delve into its evolution throughout history. From its early days to contemporary technologies, each stage has contributed to perfecting this technique, leaving significant milestones in the industrial machining landscape.

The historical evolution of CNC machining (Computer Numerical Control) is a fascinating journey spanning several decades and has undergone significant transformations in the manufacturing industry. This process has evolved from manual and conventional methods to highly sophisticated and automated systems. Below, we will explore in greater depth the key stages of this evolution:

- Beginning of Numerical Control:

In the history of CNC machining, we go back to the mid-20th century when conventional machine tools needed to be manually operated. To enhance precision and efficiency, the idea of Numerical Control systems emerged, allowing the automation of operations through numerical instructions. Although these early systems were somewhat limited in speed and capacity, they marked the beginning of a new era in machining.

- Integration of Computers:

With the advancement of computer technology, CNC machines began integrating computers for control and programming. This allowed greater complexity in manufacturing, as instructions could be more detailed and precise. The 1970s witnessed a rapid adoption of computer systems in CNC machining, improving efficiency and product quality.

- CAD/CAM Software Development:

With the incorporation of CAD (Computer-Aided Design) and CAM (Computer-Aided Manufacturing) systems, CNC machining took a significant leap in terms of design and production. The ability to model components in 3D and translate those models directly into machining instructions allowed greater flexibility and precision in production.

- Advances in Precision and Speed:

As technology progressed, substantial improvements were achieved in the precision and speed of CNC machines. The introduction of servo-controlled motors, faster spindles, and real-time feedback systems contributed to increased efficiency and reduced production times.

- Multi-Axis and Multi-Tasking CNC Machining:

The evolution continued with the development of CNC machines capable of performing operations on multiple axes simultaneously (multi-axis machining) and executing various tasks in a single setup (multi-tasking machining). These capabilities have led to greater versatility in production, allowing efficient manufacturing of more complex parts.

- Industry 4.0 and the Connectivity Era:

Currently, CNC machining is in the era of Industry 4.0, characterized by machine interconnectivity, real-time data analysis, and autonomous decision-making. The introduction of technologies such as the Internet of Things (IoT) has led to increased operational efficiency, minimizing downtime, and enabling highly personalized production.

Advantages of CNC Machining

CNC machining stands as a revolutionary technology in modern industry, offering a range of benefits that transform manufacturing processes. This innovative technique is noted for its extraordinary precision and consistency, allowing the production of complex parts with millimeter tolerances, which is crucial in sectors such as aerospace and medical.

The efficiency and speed of CNC vastly surpass traditional methods, optimizing production times and increasing operational capacity. Its ability to operate continuously maximizes productivity and reduces downtime.

A standout feature of CNC is its versatility in working with various materials and creating intricate shapes. From hard metals to plastics and woods, these machines can perform multiple operations with equal skill, opening a range of possibilities in product design and innovation.

CNC’s flexibility allows it to quickly adapt to different projects, making it ideal for prototype production and customized manufacturing. Its integration with advanced technologies such as AI and IoT further enhances its effectiveness and precision.

Additionally, CNC significantly contributes to workplace safety by automating dangerous tasks and reducing risks for operators. Its precision also lowers the likelihood of errors in critical products.

In today’s competitive landscape, CNC provides a substantial advantage to companies, enabling them to produce high-quality items efficiently and cost-effectively, swiftly responding to market demands and customer needs.

The Art in CNC Programming: Orchestrating Precision

CNC Programming: The Fusion of Science and Creativity

CNC programming goes beyond being a mere technical task; it is an art that involves the careful creation of instructions that will guide machinery in the production of complex and precise parts.

- Tool Path Generation:

One of the initial steps in CNC programming involves the generation of tool paths. Programmers must thoroughly understand the three-dimensional design of the piece and determine the optimal path the cutting tool will follow. They use specialized software that allows them to virtually visualize the machining process, adjusting parameters such as cutting speed and depth of cut. This process requires not only technical skills but also an artistic sense to optimize machining efficiency.

- Optimization of Cutting Strategies:

Efficiency in machining execution depends not only on the precision of instructions but also on the cutting strategy employed. Programmers must select strategies that minimize production time and maximize tool life. This involves making creative decisions, such as choosing the right tools, defining optimal speeds and feeds, and implementing efficient cooling techniques. CNC programming thus becomes a balancing act between speed and quality, where the programmer’s creativity plays an essential role.

- Challenges Overcome in CNC Programming:

Each CNC programming project presents unique challenges that require ingenious solutions. It could be the complicated geometry of the piece, the need to minimize vibrations during machining, or the optimization of cycle times.

- Creative Strategies to Maximize Efficiency:

CNC programming is not just about following predefined rules but finding creative ways to maximize process efficiency. This could include implementing parallel machining techniques, optimizing the sequence of operations, or adapting advanced cutting strategies. Programmers who master this art not only achieve the required precision but also optimize resources and reduce production times.

CNC Machines: The Mastery Defining Precision

The mastery of the “Art of Metalworking with Computerized Control” lies in the skill and experience of CNC machines. These machines, crucial in modern manufacturing, offer an impressive variety of distinctive capabilities.

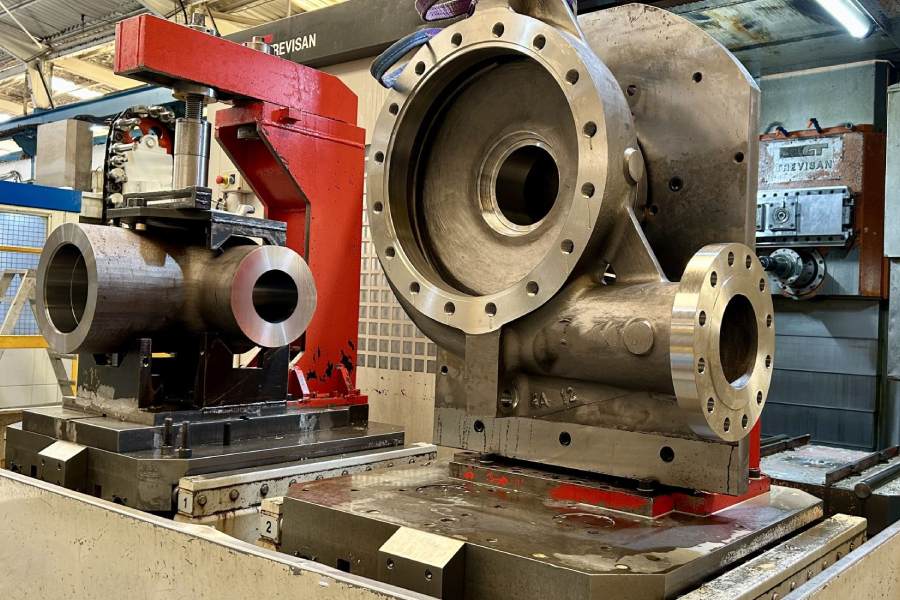

- Multi-Tasking Machining Centers:

Multi-tasking machining centers represent a notable innovation in the world of CNC machines. These machines can not only perform milling, drilling, and turning operations in a single setup but also automatically switch between tools and perform operations on multiple axes simultaneously. This comprehensive approach not only saves time but also significantly improves precision by reducing the need to reposition the workpiece.

In the current market, there are several advanced models of multi-tasking machining centers, each designed to address specific industry needs. Some noteworthy examples include:

1. Trevisan Machining Center D5 900 Fanuc 31i

2. Trevisan Machining Center DS 600 Fanuc 31i

3. Trevisan Machining Center DS 500 Fanuc 31i

4. Trevisan Machining Center D5 300 Fanuc 30i Model A

5. Trevisan Machining Center DS 300 Fanuc 31i

6. Trevisan Machining Center DS 200 Fanuc 31i

Each of these models features unique characteristics, such as multi-axis machining capabilities, efficient tool change systems, and advanced controls, making them ideal choices for the production of complex and high-precision parts.

- Numerical Control Lathes:

Numerical control lathes play an essential role in the manufacturing of cylindrical parts and rotating components. These machines enable the efficient production of shafts, gears, and other parts with rotational symmetry. Careful programming of tool paths and precise axis setup ensure quality and precision in production.

Some of the available CNC lathe models in the market include:

1. Lealde, S.M.T., Okuma CNC Lathe

2. SEDIN 15l6VF31 RAM CNCGE FANUC Series Ol – TD Vertical CNC Lathe

3. Tos, Froriep, Graffenstanden, Webster Et Bennet, Stankoimport Vertical CNC Lathe

4. Yu-Shine VLR-B50 ACT, GE FANUC Series 01 – TD Vertical CNC Lathe

The versatility of CNC lathes allows for the efficient production of complex parts with consistency and precision. Each of these models has specific capabilities, such as machining different diameters and lengths, as well as advanced control systems to ensure the highest quality standards.

It is worth noting that conventional and CNC milling machines and boring machines are also available in the market, further expanding the ability to address projects in a versatile and efficient manner. These additional machines allow manufacturers to adapt to a wide range of production requirements, from simple components to more complex and customized projects.

Axis Configuration and Advanced Clamping Systems

Axis configuration in CNC machines is critical for machining success. Depending on the complexity of the piece, machines ranging from three-axis to five-axis can be used, allowing optimal access to all faces of the workpiece. Additionally, advanced clamping systems play a crucial role in ensuring the stability of the workpiece during machining. Secure clamping contributes to precision and prevents unwanted deformations.

Specific Challenges Addressed by Each Machine Type

Each type of CNC machine addresses specific challenges in production. Multitasking machining centers are ideal for complex parts that require operations on multiple faces, while CNC lathes are indispensable for cylindrical components.

Cutting Tools and Associated Technologies: Merging Science and Art

Cutting tools represent the heart of the CNC machining process, and their constant evolution is a testament to the fusion of science and art in manufacturing.

- Laser Cooling: Elevating Cutting Speeds

Laser cooling technology has revolutionized CNC machining by allowing higher cutting speeds without compromising tool integrity. This method uses laser beams to selectively cool specific areas of the tool during operation, reducing wear and improving tool lifespan. This not only speeds up machining times but also optimizes efficiency by minimizing downtime associated with frequent tool changes.

- Advanced Materials in Tools: Robustness and Durability

The use of advanced materials in tool manufacturing has been a crucial step toward enhancing robustness and durability. Tungsten carbide alloys, high-strength ceramics, and nanotechnological coatings have elevated the capabilities of cutting tools. These materials not only resist wear and temperature but also maintain cutting precision for extended periods, contributing to consistent quality in production.

- Advanced Tool Geometry: Optimizing Performance

Advancements in tool geometry have allowed precise optimization of performance in CNC machining. More sophisticated designs, such as multiple cutting edges and specific angles, have become standard to address specific challenges in different types of machining. These advanced geometries not only improve precision but also reduce cutting forces and enhance chip evacuation, ensuring smooth and efficient operation.

- Tool Monitoring and Control: Maintaining Real-time Quality

The integration of tool monitoring and control systems has made a significant difference in CNC machining quality. Sensors embedded in tools enable real-time monitoring of variables such as temperature, vibration, and wear. This facilitates early detection of potential issues, allowing immediate adjustments and ensuring consistent quality of produced parts.

- Continuous Innovation and Customization: Adapting to Unique Challenges

Innovation in cutting tools focuses not only on general improvements but also on adapting to unique machining challenges. Customized tools, specifically designed for particular tasks, are gaining ground.

CNC Machining in Industrial Pumps and Valves: Merging Precision with Functionality

Integration of CNC Machining in Industrial Pump Manufacturing

Manufacturing industrial pumps is a discipline where precision and efficiency are imperative, and CNC machining emerges as a fundamental ally to meet these rigorous standards. Let’s delve into how this technology crucially integrates into the production of critical components for pumps, from highly complex rotors to housings requiring tight tolerances.

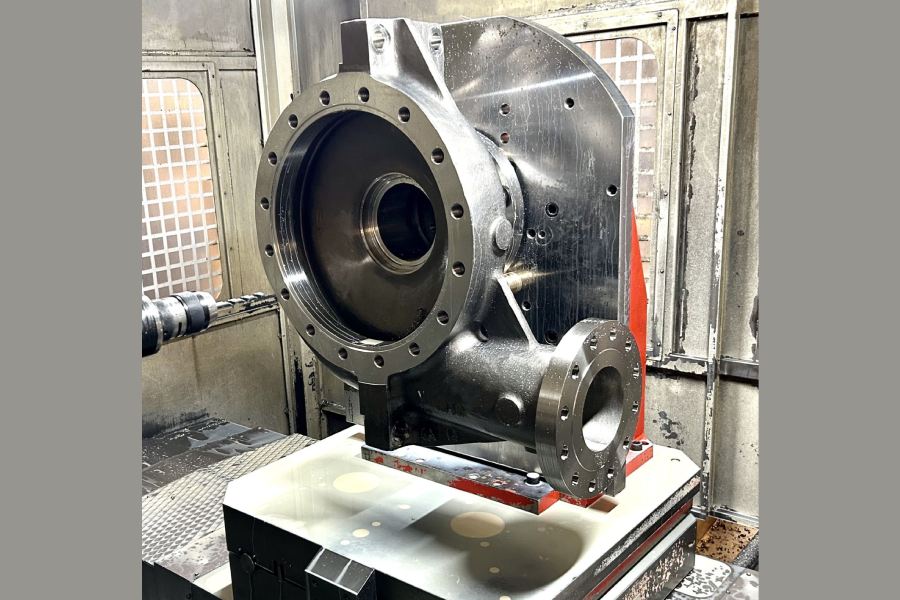

- Highly Complex Rotors:

Rotors are essential components in industrial pumps, and their intricate geometry requires millimeter precision to ensure efficient performance. CNC machining allows the creation of rotors with complex shapes and profiles, ensuring a perfect fit and optimal fluid distribution. Additionally, the capability of CNC machines to work on multiple axes simultaneously facilitates the creation of three-dimensional rotors, maximizing process efficiency and pump functionality.

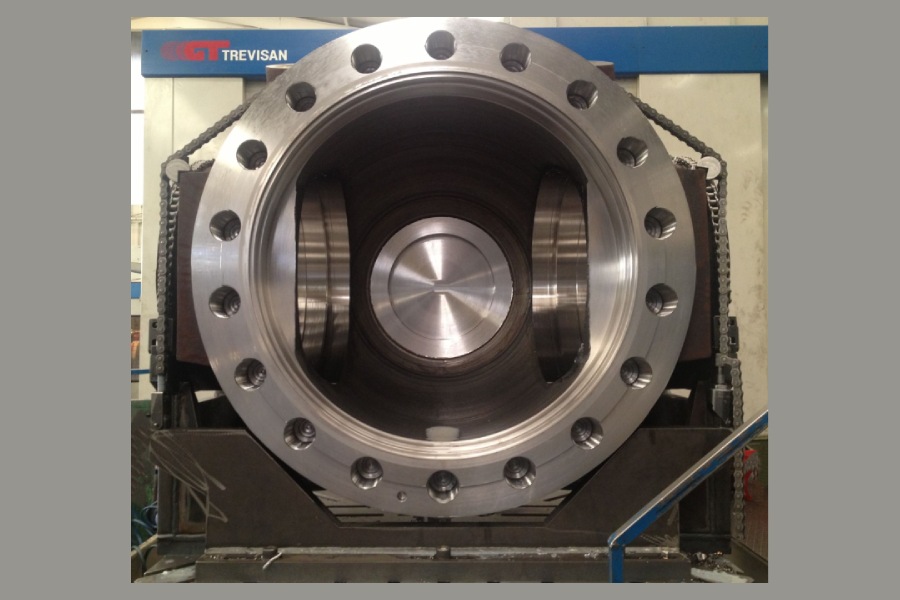

- Housings with Tight Tolerances:

The manufacturing of pump housings involves the need for tight tolerances to ensure a hermetic seal and flawless performance. CNC machining becomes the preferred method to achieve these tolerances, enabling the production of housings with smooth surfaces and precise dimensions. The ability of CNC machines to work with diverse materials, from metals to high-strength polymers, provides flexibility in material choice without compromising precision.

Industrial Valves: Where CNC Machining Mastery Shines

The manufacturing of industrial valves, an endeavor where tight tolerances and uniform surfaces are imperative, is an ideal scenario for CNC machining to showcase its mastery.

- Tight Tolerances and Uniform Surfaces:

The mastery of CNC machining is evident in the ability to work with tight tolerances, essential for the proper functioning of industrial valves. CNC machines allow the creation of components with precise dimensions, ensuring a perfect fit and eliminating any possibility of leaks. Additionally, the ability to achieve uniform surfaces contributes not only to the aesthetics of the final product but also to operational efficiency by minimizing friction and wear.

- Machining Intricate Components:

Industrial valves often require intricate components, such as seats and spheres, demanding extraordinary precision. CNC machining excels in creating these complex pieces by enabling simultaneous operations on multiple axes and meticulous tool path programming. This ensures not only dimensional accuracy but also consistency in the quality of each component.

- Adaptation to Specialized Materials:

The variety of materials used in valve manufacturing, from stainless steels to corrosion-resistant alloys, presents specific challenges. CNC machining demonstrates its excellence in adapting to these specialized materials, maintaining structural integrity and precision throughout the process. The ability to work with a wide range of materials ensures that the resulting valves are durable and resistant to adverse industrial conditions.

Current and Future Challenges of CNC Machining

Technical Challenges: Overcoming Barriers to Innovation

The introduction of CNC machining comes with its own technical challenges, and the industry continues to grapple with the responsibility of overcoming these obstacles to drive innovation.

- Efficient Management of Large Data Sets:

The increasing complexity of machined parts has led to an explosion in the amount of data generated during the CNC machining process. Efficient management of these large data sets has become a crucial challenge. Leading companies are implementing advanced data analytics solutions to extract meaningful information, thus optimizing processes and improving decision-making.

- Algorithm Optimization:

Algorithms form the backbone of CNC machining, and refining them is imperative to optimize efficiency and precision. Developing faster and more accurate algorithms is a constant challenge. The industry responds by applying advanced optimization techniques. Continuous improvement of these algorithms not only increases machining speed but also allows more efficient adaptability to different geometries and materials.

Sustainability and CNC Machining: Navigating Toward a Responsible Future

Sustainability has become imperative in the modern industry, and CNC machining is not exempt from this concern. In this section, we will examine how CNC machining addresses sustainability and highlight how the adoption of eco-efficient practices can benefit both the environment and operational efficiency.

- Waste Reduction:

CNC machining, being a material removal process, has faced criticism regarding waste generation. However, leading companies are addressing this challenge by optimizing cutting strategies to minimize material waste. Additionally, the adoption of techniques such as high-speed machining and additive manufacturing further contributes to reducing the amount of waste generated during the process.

- Eco-Efficient Practices:

Energy efficiency and the reduction of resource consumption are essential components of eco-efficient practices in CNC machining. The implementation of energy management systems, the use of efficient cooling technologies, and the optimization of machining processes to reduce tool consumption are adopted strategies to minimize the environmental footprint. Furthermore, the constant pursuit of more sustainable materials and eco-friendly processes is transforming how CNC machining is conceived and executed.

Metal in CNC Machining: Exploring Alloys and Future Applications

Metals Used in CNC Machining: Beyond Iron and Steel

The variety of metals used in CNC machining goes beyond traditional iron and steel alloys. In this section, we will delve into the exploration of various alloys, from aluminum to titanium, highlighting the unique properties of each metal and how these characteristics influence machining strategy.

- Aluminum:

Aluminum is a common choice in CNC machining due to its lightweight nature, excellent thermal conductivity, and corrosion resistance. Its relative softness facilitates machining, but considerations for chip formation and heat control are key.

- Titanium:

Titanium, known for its exceptional strength and low density, presents unique challenges in CNC machining due to its low thermal conductivity and tendency to adhere to tools.

Future Innovations: Advanced Metals and Emerging Trends

Continuous research and development in the CNC machining industry are leading to the exploration of advanced metals and emerging trends. In this section, we will investigate future innovations that push the boundaries of CNC machining, enabling the creation of lighter, stronger, and more efficient components.

- Super Alloys:

Super alloys, primarily composed of nickel, cobalt, and iron, offer exceptional resistance to high temperatures and corrosive environments. CNC machining is adapting to work with these alloys, used in aircraft turbines, rocket engines, and advanced energy applications.

- Nanometric Compounds:

Nanometric compounds, including materials like graphene, offer unique properties due to their nanoscale structure. CNC machining is evolving to work with these advanced materials, opening the door to revolutionary applications in electronics, nanotechnology, and biomedical engineering.

- Implications on Design and Machining:

These innovations in advanced metals impact CNC machining design and operations. The need for specialized cutting tools, adaptive machining strategies, and a precise focus on temperature management are crucial considerations to fully leverage these emerging trends.

Innovations and Emerging Technologies in CNC

In this exciting universe of CNC machining, technological innovations are constantly evolving. From the use of advanced materials to the implementation of optimization algorithms, manufacturers are exploring new ways to enhance efficiency and quality in the production of industrial valves. These advances are paving the way towards a future where precision and customization are the norms, propelling the industry towards even more thrilling horizons.

Delve into the exciting universe of CNC machining, where “Technological Innovations in Industrial Valve Manufacturing” are opening new frontiers in precision and customization. Discover how these technologies are driving significant advancements in the manufacturing of metal components, shaping the future of the industry.

In this intriguing sector, where each piece tells a story of precision and quality, it is important to highlight the Metrology and Quality Inspection Room. This article, a key piece in our series, invites you to explore how this place becomes the meticulous guardian of accuracy. From state-of-the-art measuring and testing instruments such as the measuring arm to breathtaking inspection processes, the room stands as the epicenter where every meticulous detail matters.

We encounter an exceptional tool that goes beyond engineering, leaving its mark in crucial sectors. In the dynamic field of oil & gas, CNC machining is not limited to manufacturing but becomes an essential ally, precisely sculpting vital components for resource exploration and extraction. In this context, the importance of fittings in the oil and gas industry stands out as they play a fundamental role in the integrity and efficiency of systems, ensuring secure and durable connections essential for the smooth operation of oil operations. Navigating into the unknown, this technological art also displays its prowess in naval construction, creating fundamental pieces that withstand the most challenging tides.

In the world of paper pulp, CNC machining becomes a master craftsman, precisely carving engineering solutions that drive efficient production and engineering solutions for handling industrial pumps and valves. The dance of numbers and algorithms comes to life in petrochemicals, where these advanced techniques shape essential components, merging science and art in every created piece. In the nuclear field, this technological art not only shapes components but also the future of power generation. Immerse yourself in extreme temperatures with cryogenics, where CNC machining is a precise symphony in creating cold-resistant components, such as cryogenic valves and cryogenics pumps.

Exploring the vastness of the sea, this innovative technique also dives into desalination, providing crucial solutions in water purification. And as the guardian of our resources, CNC machining finds its purpose in water and wastewater treatment, carving a path towards sustainability.

In the flow of this process, flow control valves, playing a pivotal role in engineering, act as masters of regulation. In the context of the naval industry, these valves precisely orchestrate the movement of vital fluid, both in water production and intricate naval systems, redefining efficiency standards in every corner of this complex engineering odyssey.

This article becomes your reliable ally in exploring how precision in CNC machining is not just a technical skill but a true artistic expression. In this journey, we will decipher the mysteries that make every detail in metal creation exceptional, unraveling its complexities, and highlighting its essential role in handling industrial pumps and valves.

CNC Industrial Applications

CNC machining has revolutionized numerous industrial sectors, offering precise and efficient solutions for a wide range of applications. Its versatility and ability to produce complex parts have made it an indispensable technology in various fields:

- Aerospace Industry: CNC is crucial in the manufacturing of high-precision components for aircraft and spacecraft, such as turbines, fuselages, and landing gear parts.

- Automotive: It is used to produce engine blocks, transmissions, and precision components for braking and steering systems.

- Medicine: CNC technology is essential in creating customized implants, prosthetics, and high-precision medical equipment.

- Electronics: It facilitates the production of device casings, printed circuit boards, and miniaturized components.

- Energy: It is employed in manufacturing wind turbines, components for solar panels, and parts for nuclear reactors.

- Military and Defense Industry: Produces components for weaponry, armored vehicles, and communication systems.

- Maritime Industry: It is used in the manufacturing of propellers, shafts, and other critical components for vessels.

- Molds and Dies: CNC is essential in creating plastic injection molds and dies for metal stamping.

- Oil and Gas Industry: Manufactures precision valves, drilling bits, and other corrosion-resistant components.

- Textile Industry: Produces parts for looms and industrial sewing machines.

- Construction Sector: It is used in the manufacturing of customized architectural components and specialized tools.

- Food Industry: Creates parts for food processing and packaging machinery.

The versatility of CNC allows its application in virtually any sector that requires the manufacturing of parts with high precision and repeatability. Its ability to work with a variety of materials, from metals to plastics and composites, makes it an indispensable tool for product innovation and development in multiple industries.

Additionally, CNC has facilitated mass customization, allowing companies to produce small batches of highly personalized products efficiently and economically.

Conclusion

CNC machining has established itself as a revolutionary and versatile technology that has transformed modern manufacturing industry. Throughout this article, we have explored the most relevant and key aspects of this technology:

- Evolution and fundamentals: From its beginnings to the current era of Industry 4.0, CNC machining has undergone constant evolution, integrating advances in computer science, CAD/CAM software, and connectivity.

- Significant advantages: Exceptional precision, improved efficiency, versatility in materials and shapes, flexibility in design and production, and contributions to workplace safety are some of its most notable advantages.

- Diverse industrial applications: Its use extends to critical sectors such as aerospace, automotive, medicine, energy, and oil and gas, among others, demonstrating its adaptability and essential role in modern manufacturing.

- Innovation in machinery and tools: Advances in multitasking machining centers, CNC lathes, and cutting tools with advanced technologies have expanded the capabilities and efficiency of CNC machining.

- Challenges and future: Managing large datasets, optimizing algorithms, and seeking more sustainable practices are current challenges driving continuous innovation in the sector.

- Impact on specific industries: Its crucial role in the manufacturing of industrial pumps and valves, as well as in sectors like oil & gas, naval, and petrochemicals, among others, has been highlighted.

- Sustainability and efficiency: CNC machining is evolving towards more eco-efficient practices, aiming to reduce waste and optimize resource utilization.

CNC will continue to play a crucial role in the evolution of manufacturing, constantly adapting to changing market demands and emerging technologies. A clear example of this adaptation is observed in the petrochemical industry, where, these advanced techniques are integrally involved in the production of essential components. From the meticulous creation of intricate rotors to the manufacturing of high-precision valves, CNC machining proves to be an indispensable ally, transcending the realm of traditional mechanical engineering and redefining production standards in highly specialized sectors.