Butterfly Valves’ Applications in Industry.

Butterfly valves have become key components in various industrial applications due to their simple design, flexibility, and efficiency. This text provides a detailed analysis of the properties and uses of butterfly valves, offering a general overview of how they contribute to optimizing processes in different sectors. From their initial development to their integration in the Industry 4.0 era, butterfly valves have proven vital in enhancing both the effectiveness and robustness of industrial systems.

Within the range of available industrial valves, such as diaphragm valves or needle control valves, butterfly valves stand out for their ability to control large flow rates with minimal pressure loss.

These devices, which operate with a rotating system, are suitable for scenarios that require quick and tight sealing. They are often used in water supply networks, wastewater treatment plants, and in the chemical and petrochemical sectors.

Asimer Group has extensive experience in these sectors, not only with valves but also with pumps and fittings.

The manufacturing process for valves has significantly advanced with the adoption of modern technologies like TIG welding and CNC machining, allowing for precise and efficient production. This technology ensures that butterfly valves meet the highest quality standards, guaranteeing optimal performance and increased durability.

Furthermore, through the use of advanced materials and innovative manufacturing techniques, valves have been created that can withstand corrosive environments and extreme conditions.

The integration of butterfly valves into Industry 4.0 has revolutionized their application and monitoring. With the use of advanced measurement and testing instruments, such as measuring arm and other machining tools, industries can now precisely monitor and control valve performance in real-time, significantly improving system energy efficiency. This not only reduces operational costs but also contributes to environmental sustainability by minimizing resource consumption and pollutant emissions. Industry 4.0 and the CNC machining revolution are profoundly transforming automation and precision in modern industrial processes.

Butterfly valves are essential components in the modern industrial landscape. Their versatility, combined with technological advancements in their manufacturing and monitoring, makes them indispensable for various industrial applications.

Chemical and Petrochemical Industries

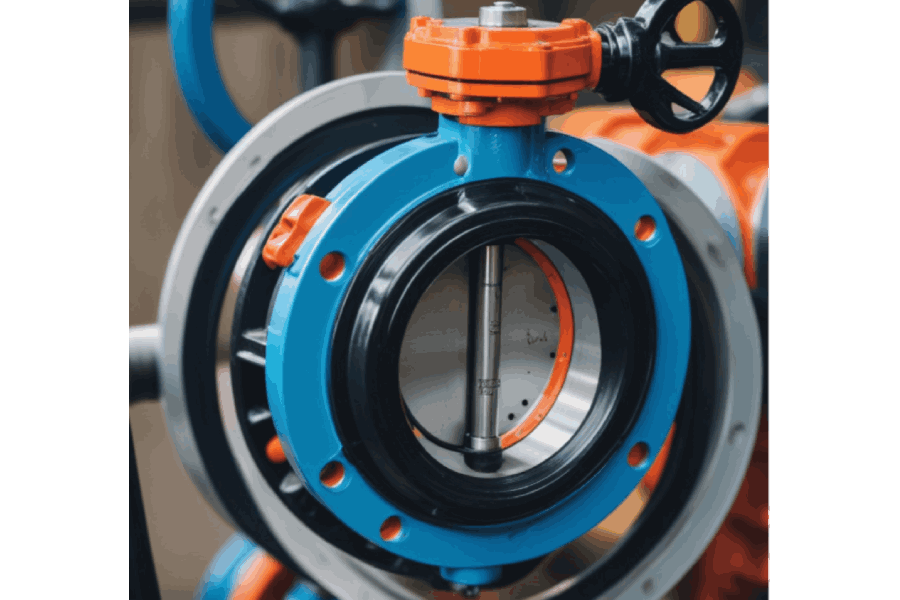

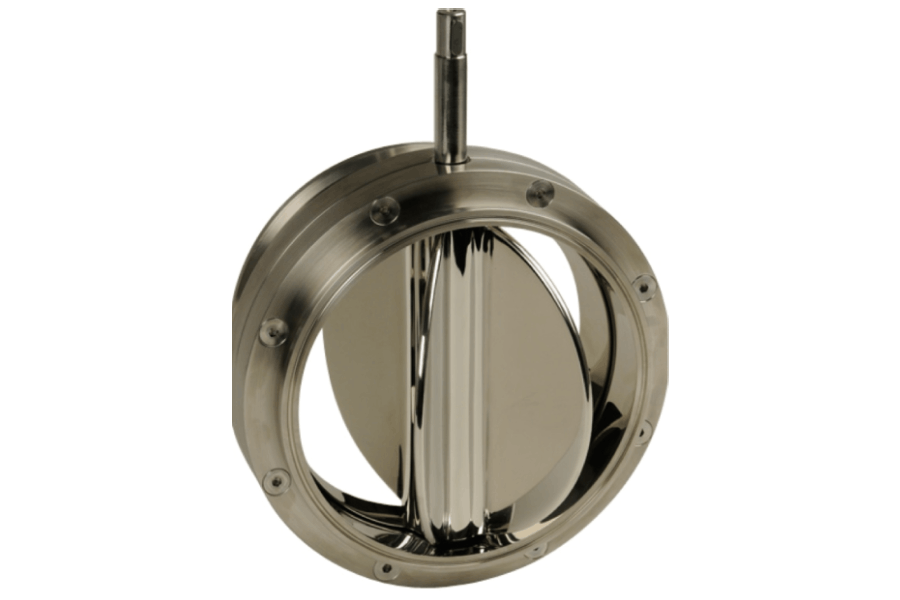

Butterfly valves play a fundamental role in the chemical and petrochemical industry as they offer efficient control of the flow of chemicals and hazardous materials. These valves are characterized by their compact design and their ability to regulate the flow in large-diameter pipelines. How do they work? Their operation consists of a circular plate that rotates on a central axis, allowing the opening and closing of the conduit to be adjusted. In the chemical industry, butterfly valves are frequently used in the transfer of corrosive chemicals, flammable liquids, and toxic substances.

They are used, for example, in the precise measurement of chemical compounds during manufacturing, in regulating the flow of acids and solvents in pharmaceutical production, and to control the movement of hazardous liquids in wastewater treatment plants. In the petrochemical industry sector, they play a vital role in managing hydrocarbons by enabling safe and efficient control of crude oil, gas, and refined products flow.

In the plastics and polymers manufacturing sector, these valves are used to handle monomers and other reactants, ensuring a homogeneous mixture and preventing cross-contamination. Butterfly valves control the flow of ammonia, sulfuric acid, and other essential compounds in the synthesis of agrochemical products in fertilizer plants.

Furthermore, their robust structure and ability to withstand high pressures and temperatures make them a reliable and safe option in industrial environments where hazardous substances are managed. Butterfly valves are made from corrosion-resistant materials such as stainless steel, Hastelloy, and other special alloys, ensuring long service life and reliable performance even in extreme conditions.

The ease of maintenance and the ability to operate with automatic actuators also contribute to their popularity in industrial applications. Pneumatic, electric, or hydraulic actuators allow for remote and precise operation, enhancing safety and operational efficiency.

Additionally, the ability of butterfly valves to provide a tight seal minimizes the risk of leaks, which is crucial when handling hazardous substances.

This ensures the safety of employees and the environment, while also complying with rigorous workplace safety and environmental regulations.

Food and Beverage Industry

Butterfly valves play an essential role in the food and beverage industry by providing an efficient and reliable solution for controlling the flow of raw materials, finished products, and cleaning liquids. These valves are widely used in various stages of the manufacturing process, from handling raw materials to final packaging. Their compact design and ability to provide a tight seal make them a popular choice in this industry.

In the food industry, butterfly valves are essential for regulating the flow of ingredients such as liquids, pulps, and viscous mixtures, ensuring precise and consistent dosing. They are also used to control the flow of finished products, enabling efficient packaging and proper quality control. These valves are particularly useful in beverage production, where precise flow regulation is required for filling bottles and cans uniformly and quickly, preventing spills and waste

Moreover, butterfly valves are used to handle cleaning liquids, disinfectants, and sanitary solutions, which are essential for maintaining high hygiene standards in the food industry. Their clean design and easy maintenance facilitate operation and ensure safe, contamination-free production.

The ability of butterfly valves to operate under high pressure and temperature conditions is also crucial in pasteurization and sterilization processes, where strict flow control is needed to eliminate pathogens without compromising product quality. In applications involving dairy products, juices, and carbonated beverages, butterfly valves ensure a smooth transition between different stages of production, maintaining consistency in flavor and texture of the final product.

Furthermore, butterfly valves are configured to meet hygiene and food safety standards, such as those established by the FDA and USDA.

This includes the use of high-end materials such as stainless steel and food-grade elastomers, which are robust, corrosion-resistant, and easy to clean.

The capability to integrate these valves into automated systems also enhances operational efficiency, allowing for remote control and constant monitoring of liquid flow, reducing downtime and operational costs.

Energy and Power Generation

In the energy and power generation industries, butterfly valves play a fundamental role by providing a reliable and efficient solution for regulating the flow of liquids and gases in piping systems. These valves are frequently employed in power plants, including thermal, nuclear, and renewable energy facilities.

In power plant piping systems, butterfly valves allow for regulating the flow of liquids and gases at various process stages. They are used in the intake of water to turbines, controlling the amount of liquid admitted to generate energy. Additionally, they control the flow of combustion gases, ensuring efficient combustion and reducing emissions. Butterfly valves are also critical in steam distribution systems, regulating the flow and pressure of steam used to drive turbines and generate electricity, ensuring stable and efficient operation.

Another way butterfly valves are used in the energy industry is in cooling systems. These valves enable the regulation of water or coolant flow in critical equipment like generators and condensers.

In nuclear power plants, butterfly valves are crucial for managing emergency cooling systems, where precise control of the coolant flow is essential to ensure the reactor’s safety and stability.

In renewable energy plants such as hydroelectric and solar thermal plants, butterfly valves are used to control the flow of liquids in energy storage systems, such as tanks of molten salts, which store heat for conversion into electricity.

Besides their application in flow control and cooling systems, butterfly valves are also employed in the management of liquid and gaseous waste in power plants. These valves allow for the regulation and isolation of waste flows, facilitating their safe treatment and disposal. Their ability to withstand high pressures and temperatures, along with their corrosion resistance, makes them ideal for these demanding applications.

Pharmaceutical and Biotechnology Industries

Butterfly valves are commonly used in the pharmaceutical and biotechnological industries for their ability to regulate flow at various stages of chemical, pharmaceutical, and biological product manufacturing. These valves provide a reliable solution for precisely controlling liquids and gases in pipeline systems, ensuring accuracy and safety in processes.

In pharmaceutical production, butterfly valves are essential for directing the flow of active ingredients, excipients, and solvents. They enable precise and controlled dosing, ensuring the quality and consistency of pharmaceutical products. Their ability to seal tightly is crucial for preventing contamination between production batches, maintaining the high standards of purity and quality required by the industry.

Butterfly valves are also used to control the flow of chemicals, reagents, and cell cultures in chemical and biological manufacturing. In fermentation and bioprocessing processes, these valves allow precise control of nutrient and gas supply needed for the growth of cell cultures and microorganisms, optimizing process efficiency and final product quality. This ensures an efficient and safe production process, preventing spills or unwanted contaminations.

Furthermore, butterfly valves play a significant role in cleaning and sterilizing equipment systems in the pharmaceutical and biotechnological industry. They enable efficient circulation of cleaning and sterilizing agents through production equipment, ensuring all system components remain free of contaminants. Additionally, the ease of automation of butterfly valves allows integration into advanced process control systems, enhancing accuracy, reducing manual intervention, thereby minimizing the risk of human errors and increasing operational efficiency.

Water and Wastewater Treatment

Butterfly valves are essential elements in the water and wastewater treatment sector, offering an efficient and reliable solution for flow control in water supply systems, treatment plants, and sewer networks.

In water supply systems, butterfly valves regulate the flow of drinking water to consumers, ensuring equitable and efficient distribution. Their ability to operate in large-diameter pipes makes them ideal for applications in municipal and industrial networks, where robust flow control of large water volumes is required. Additionally, they are used in sewer networks to control the flow of wastewater and prevent overflows or contamination issues. In emergencies such as floods or system failures, butterfly valves can act immediately to isolate affected sections and minimize service and environmental impact.

Butterfly valves play a vital role in water treatment plants by regulating flow at various stages of the process, such as filtration, sedimentation, and disinfection.

These valves enable precise dosing of necessary chemicals such as coagulants and disinfectants for effective water treatment. With their capability for precise control of water flows, they contribute to ensuring the quality and safety of drinking water supply. Additionally, their corrosion-resistant construction ensures long-term durability even in challenging environments, such as exposure to aggressive or chemically treated waters.

In agricultural production, butterfly valves are vital in irrigation systems by regulating the supply of water to crops, thus optimizing water resource usage and improving irrigation efficiency. Their ease of operation and maintenance makes them a popular choice for both agricultural and industrial applications.

Butterfly Valves in the Pulp and Paper Industry

Butterfly valves are crucial in the paper pulp manufacturing sector for their ability to provide precise and effective control of liquid and gas circulation in various stages of production.

In this sector, where closely monitoring flow is crucial to ensuring the quality of the final product and operational efficiency, butterfly valves stand out as an optimal choice.

Flow Control in Pulping Processes

In the pulping phase, where wood is transformed into pulp through mechanical or chemical processes, butterfly valves are fundamental for regulating the flow of reactants and chemical solutions. These reactants, containing products like sodium sulfate and sodium hydroxide, are necessary to separate cellulose fibers from lignin. Butterfly valves allow precise control of these chemical supplies, optimizing the pulping process and ensuring product efficiency and quality.

Fluid Management in Pulp Bleaching

The pulp bleaching process is a critical procedure in paper manufacturing, involving bleaching agents to enhance pulp whiteness and purity. Butterfly valves control the flow of bleaching agents such as chlorine dioxide and hydrogen peroxide, allowing precise and safe dosing. This control is crucial for producing high-quality products and reducing the environmental impact of the process.

Application in Water Recycling Systems

The pulp and paper industry is extremely water-intensive, making efficient water management crucial. Butterfly valves are used in water recycling and treatment processes at paper mills. They regulate the flow of reused and treated water, ensuring it meets the necessary quality standards for various stages of the manufacturing process.

Flow Control in Paper Machines

In paper machines, where pulp is transformed into continuous sheets of paper, butterfly valves are essential for controlling the flow of water and additives. These valves ensure that the right amount of water and additives, such as starch and resins, are evenly applied to the pulp, which is crucial for producing consistently high-quality paper.

Regulation of Steam and Compressed Air

In addition to liquid control, butterfly valves are vital for regulating the flow of steam and compressed air used in various processes within the paper plant. Steam is needed for drying pulp and paper, while compressed air is used in automation and control systems. Butterfly valves provide precise regulation of these flows, enhancing the plant’s energy efficiency and operational effectiveness.

Ease of Maintenance and Operation

Butterfly valves can be installed and operated in small areas, and are easy to clean and maintain, which reduces downtime and operating expenses.

Additionally, their ability to integrate with automatic control systems improves the precision and efficiency of the manufacturing process.

Durability and Resistance

The durability and resistance of butterfly valves make them suitable for the demanding conditions of the pulp and paper industry. They are designed to withstand high pressures and temperatures and to resist corrosion from harsh chemicals and mechanical wear.

Conclusion

In conclusion, butterfly valves are essential components in industrial fluid management due to their versatility and ability to ensure precise and reliable flow control across a wide variety of industrial applications. Their robust design and capability to operate in demanding conditions make them a preferred choice in diverse sectors, including chemical, petrochemical, food, pharmaceutical, energy, and water treatment industries.

These valves play a crucial role in optimizing industrial processes by ensuring efficient regulation of liquid and gas flows, which is fundamental for maintaining operational efficiency and safety in industrial facilities. Their ability to handle large fluid volumes and withstand high pressures and temperatures makes them ideal tools for environments requiring rigorous and reliable flow control.

Additionally, butterfly valves offer significant advantages in terms of installation and maintenance. Their compact design simplifies integration into existing systems, and their straightforward structure reduces installation and operational costs. The ease of automating these valves also contributes to optimizing operational efficiency by reducing human intervention and minimizing error risks.

In summary, butterfly valves are not only essential for efficient fluid management in various industries but also key to ensuring safety, reliability, and profitability in modern industrial processes. Their adaptability and performance make them a critical component in achieving efficient, safe, and sustainable industrial operations.