Measuring instruments in industrial metrology: A practical guide to dimensional control for pumps and valves

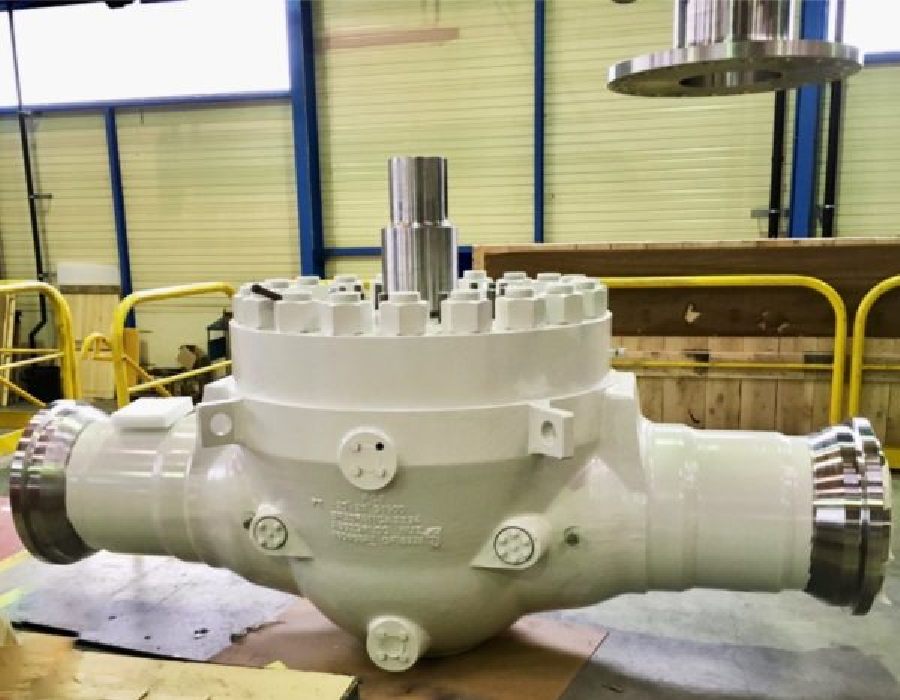

Measuring instruments in industrial metrology aren’t “tools”: they’re the point where it’s decided whether a part meets the drawing and tolerances or becomes a hidden cost (rework, rejections, delays, and disputes with the OEM). In critical components such as casings, covers, shafts, or impellers for industrial pumps and valves, dimensional accuracy stops being a theoretical …