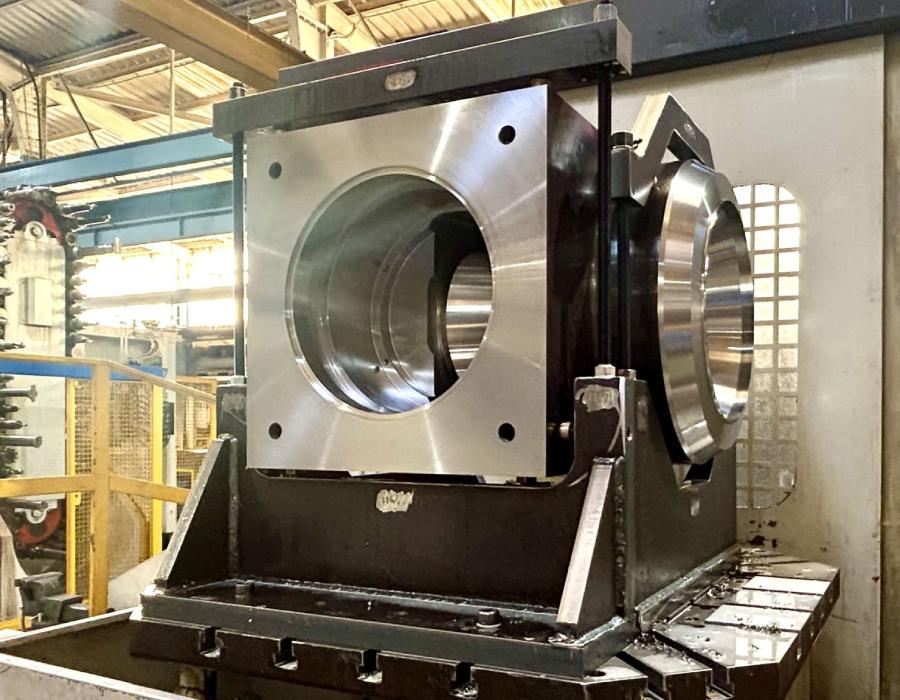

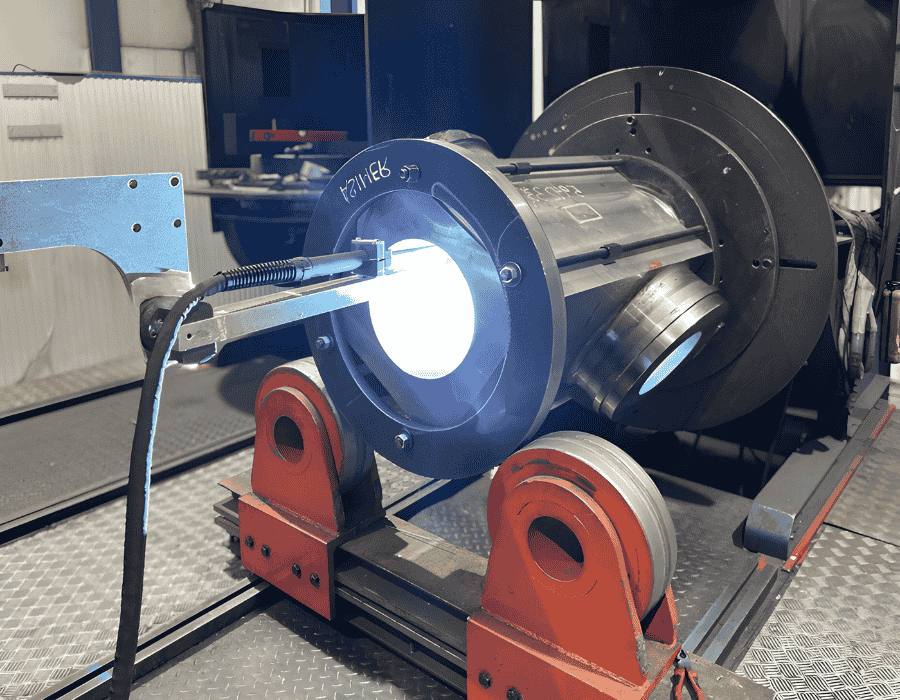

Machining and welding for industrial predictive maintenance: solutions for pumps, valves and compressors

Machining and welding for predictive industrial maintenance is key to ensuring reliability and extending the service life of pumps, valves and compressors. In sectors such as Oil & Gas, cryogenics or water treatment, these solutions allow you to anticipate failures, optimize costs and reduce the risk of unplanned shutdowns. These solutions may include the machining …