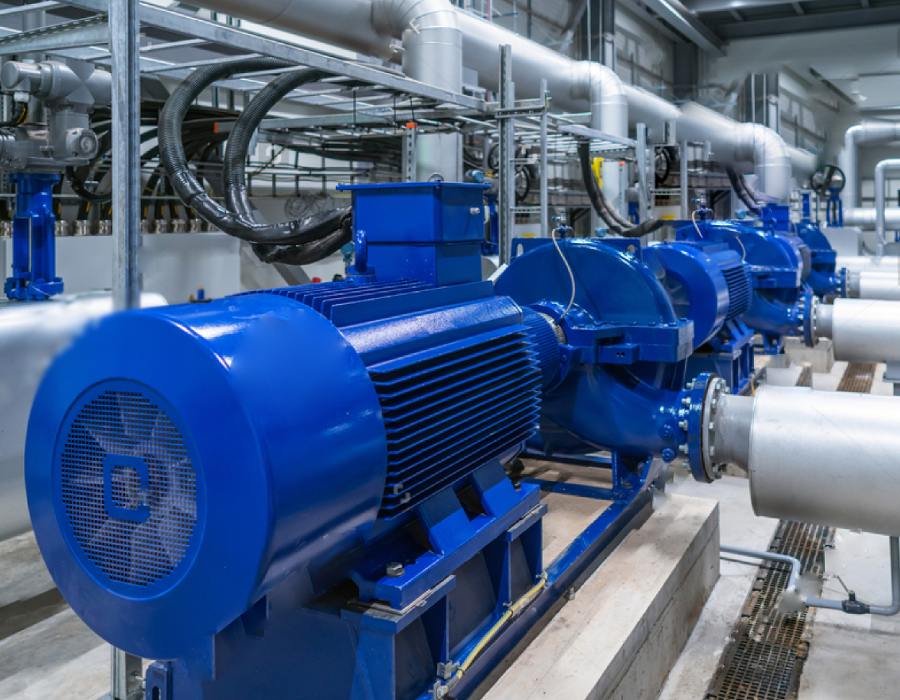

Industrial pumps are critical equipment in plant: if they fail, the process stops, maintenance is triggered and availability drops. Therefore, in addition to knowing types and applications, it is key to understand which variables influence their performance (fluid, flow rate, pressure, temperature, materials and operating conditions) and which parts are really sensitive to wear, corrosion or tightness problems.

In the current context, Industry 4.0 and CNC technology are changing the standard: more dimensional control, more repeatability and better traceability. In projects where the component is critical (housings, covers, shafts, impellers or sealing zones), CNC machining makes the difference in reliability, efficiency and service life.

What are industrial pumps and what are they used for?

An industrial pump is a mechanical piece of equipment designed to move fluids (liquids or gases) within a process, generating flow and pressure to transfer the fluid from one area to another. They are used in sectors such as chemical, petrochemical, naval, cryogenics, desalination, water treatment, and Oil & Gas, among others.

From the industrial user’s perspective, what really matters is not the pump as an abstract component, but the outcome it delivers: process continuity, stable energy consumption, and a controlled total cost of ownership (maintenance, spare parts, and downtime). This is where factors such as energy efficiency, correct pump type selection, and the actual condition of internal components become critical. At installation level, flow regulation also plays a key role: the valve and its hydraulic behavior can increase pressure losses and energy consumption, which is why it makes sense to complement this approach with a focus on energy efficiency in industrial valves.

Why precision and component quality matter

In industrial pumps, many issues originate from “small” details:

- Out-of-tolerance clearances in fitted areas

- Inadequate surface roughness on critical surfaces

- Misalignments caused by deformation or residual stresses

- Accelerated wear due to abrasion or cavitation

- Poor sealing resulting from geometry or surface finish

That’s why, in pump projects, accuracy CNC machining is not an “extra”: it is a prerequisite for stable operation and consistent performance over time.

When we talk about machining-based production projects, it’s not just about “making a part”, but about ensuring tolerances, concentricity, flatness, surface finishes, and proper verification in the metrology room using calibrated measuring instruments.

Types of industrial pumps and when they are used

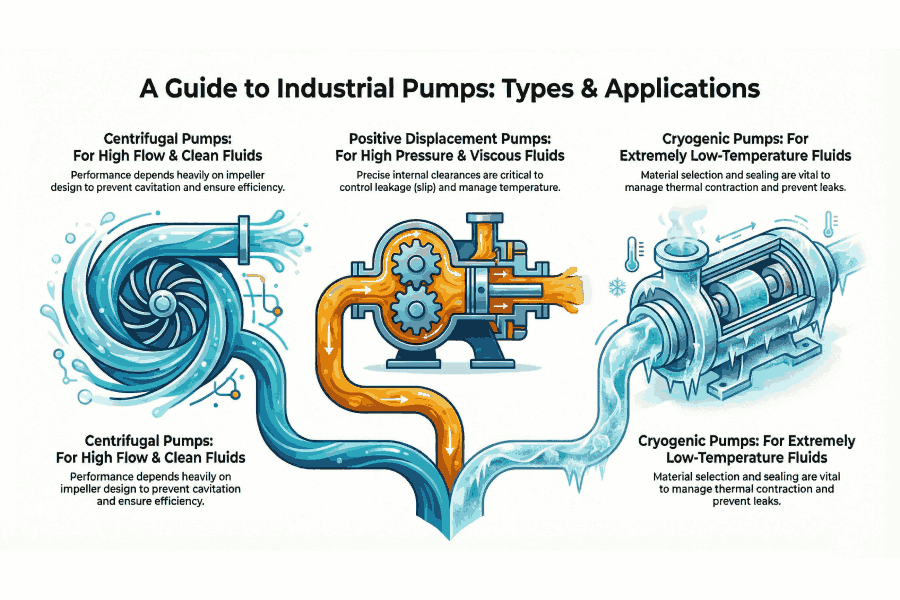

Centrifugal pumps

The centrifugal pump is the most common option for handling large flow rates with relatively clean fluids. Its performance depends heavily on the hydraulic design, the operating point, and variables such as NPSH (linked to cavitation). If you want to understand the logic by sector, we encourage you to read our article Industrial applications of centrifugal pumps.

In centrifugal pumps, the geometry of the impeller and casing, as well as the surface finish in critical areas, directly influence vibration, efficiency, and cavitation risk. To go deeper into this topic, see our content on parts of a centrifugal pump.

Positive displacement pumps (gear, piston, screw, etc.)

These are used when precise flow control, higher pressures, or viscous fluids are required. In such cases, control of internal clearances and surface finish is especially critical, as they directly affect internal leakage (slip), volumetric efficiency, and operating temperature.

Cryogenic pumps

Cryogenic pumps handle fluids at extremely low temperatures, where material selection, thermal contraction, and tight sealing are critical. If you want to explore this type of equipment and its real plant applications, you can find more details in Applications of cryogenic pumps.

And to understand why cryogenics imposes such strict requirements materials, tolerances, quality control, and reliability in highly demanding sectors, here is a very illustrative example: Applications of cryogenics.

How industrial pumps work

Think of it this way:

- The pump “takes in” fluid through the inlet (suction).

- An internal element (impeller / piston / gears) adds energy to it.

- The fluid leaves through the discharge with higher pressure or useful flow.

A pump does not “create” fluid; it converts energy from the motor into hydraulic energy. If the system is poorly defined (valves, piping, filters, viscosity, temperature), the equipment suffers and performance degrades, even if the pump itself is well designed.

Critical components and what tends to fail

In an industrial pump, most issues are concentrated in a few critical areas:

- Casing / body: erosion, cavitation, corrosion, and deformation.

- Covers and sealing interfaces: leakage, deformation, and loss of flatness.

- Shaft: misalignment, wear in bearing or seal housings, and vibration.

- Impeller: cavitation, erosion, and imbalance.

- Sealing areas: geometry and surface finish directly determine leakage rates and seal service life.

In projects where Asimer Group participates as a partner, the value usually lies in ensuring geometry + surface finish + verification, combining CNC machining by material removal (chip removal) with industrial criteria for dimensional control and repeatability. This approach is supported both by the proper selection of CNC machining tools and by defining the process according to component type, tolerances, and material, as developed in CNC machining applications.

When the component requires joining, repair, or localized material build-up in specific areas, TIG welding is used for its precise thermal control and the high quality it delivers in critical zones. To understand when TIG is suitable and when MIG, you can see the comparison in differences between TIG and MIG welding.

Industrial pumps in oil & gas: why the environment punishes so much

In Oil & Gas, the type of fluid, process temperatures, and the presence of contaminants can accelerate wear and corrosion. Moreover, the cost of a failure is not limited to the repair itself: it often involves shutdowns, production losses, and operational risks. That’s why the objective should not be to “cheap out on a part”, but to reduce failures and downtime through a reliability-driven approach, dimensional control, and the correct selection of materials and surface finishes. In this context, it is worth reviewing how to optimize costs in the machining of pumps and valves without compromising quality or service life.

And when we talk about truly demanding environments, refining is a clear example: the nature of products and by-products, the presence of aggressive compounds, and wide temperature and pressure ranges ultimately define requirements for compatibility, wear resistance, and maintenance in pumps, valves, and auxiliary equipment. This context helps explain why certain decisions related to materials, welding, or machining are critical: oil refining.

Maintenance: how to avoid unnecessary downtime and costs

In industrial pumps, effective maintenance is not about reacting when something breaks, but about detecting signs of degradation before a shutdown becomes inevitable. Vibrations, changes in flow rate, temperature, noise, wear in sealing areas, or dimensional deviations usually appear long before failure, and acting in time makes a decisive difference in availability and total cost.

If you want to compare approaches and understand which strategy reduces failures and costs the most in critical components, you can explore it in detail here: predictive machining maintenance vs. corrective maintenance.

And if your goal is to turn this into a practical decision (what to inspect, which technique to apply, and how to choose the right service depending on the type of equipment and environment), this guide helps you structure it: predictive maintenance services: how to choose the most suitable one.

In environments where pump failure has a direct impact on production, the combination of diagnosis plus technical intervention on the component (machining and/or welding) is key to restoring tolerances, sealing performance, and reliability. Here is an applied approach for pumps, valves, and compressors: machining and welding for industrial predictive maintenance.

How to choose an industrial pump without mistake

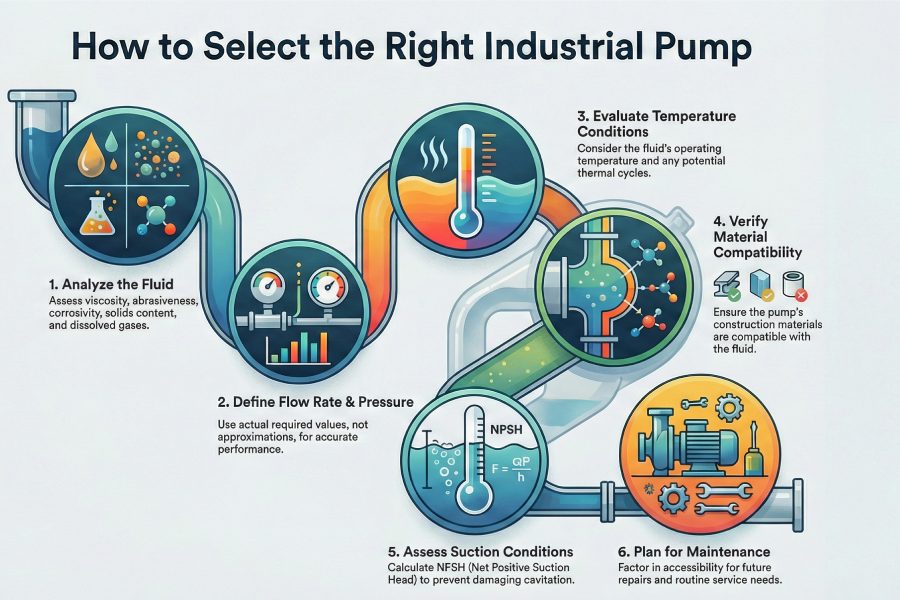

Before making a decision, define the following (in this order):

- Fluid: viscosity, abrasiveness, corrosivity, solids content, dissolved gas

- Actual flow rate and pressure (not “approximate” values)

- Temperature and variations (thermal cycles)

- Materials and compatibility

- Suction conditions (NPSH and cavitation risk)

- Maintenance criteria and accessibility

Proper selection reduces energy consumption and extends service life.

Industrial pumps and Asimer Group: practical approach for OEMs

Asimer Group is a machining company and technical partner for industrial pump projects where the component requires precision, repeatability, and quality control especially in critical parts such as casings, covers, shafts, impellers, or sealing areas.

If you are evaluating a project (part made to drawing or sample, complex material, tight tolerances, or the need for specialized welding), the most efficient approach is to clearly define the technical problem from the outset: fluid, operating conditions, critical geometry, and the objective (reliability, tightness, durability, total cost).

Do you need machining or welding for industrial pump components?

Tell us your industry, fluid (abrasive/corrosive/viscous), pressure/temperature and the component (casing, covers, shaft, impeller or sealing areas). We will get back to you with a technical assessment.

Request technical assessment

FAQs on industrial pumps

1) What is the difference between a centrifugal pump and a positive displacement pump?

A centrifugal pump is ideal for large flow rates and low-viscosity fluids, while a positive displacement pump is better suited for viscous fluids, higher pressures, or applications requiring very precise flow control.

2) What causes cavitation in a pump?

Typically insufficient available NPSH, poorly designed suction, high fluid temperature, or excessive losses in the suction line. Cavitation usually damages the impeller and the casing.

3) Which parts wear out first in an industrial pump?

The impeller, casing in flow passages, shafts in bearing or seal housings, covers, and sealing areas. Wear depends on the fluid characteristics and the operating point.

4) What quality controls are common for critical components?

Dimensional inspection (CMM or dedicated fixtures), verification of surface roughness, concentricity, and flatness, and when applicable non-destructive testing such as liquid penetrant inspection.

5) How do I know whether it’s better to repair a part or remachine it?

It depends on the material, geometry, tolerances, failure history, and criticality of the component. When the cost of downtime is high, prioritizing reliability and traceability is usually the best option.