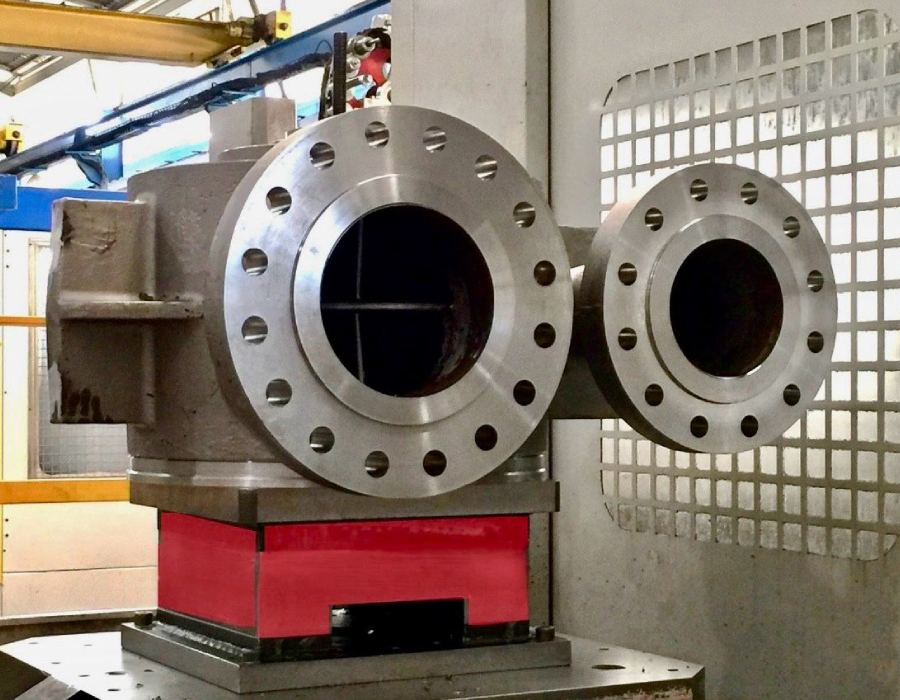

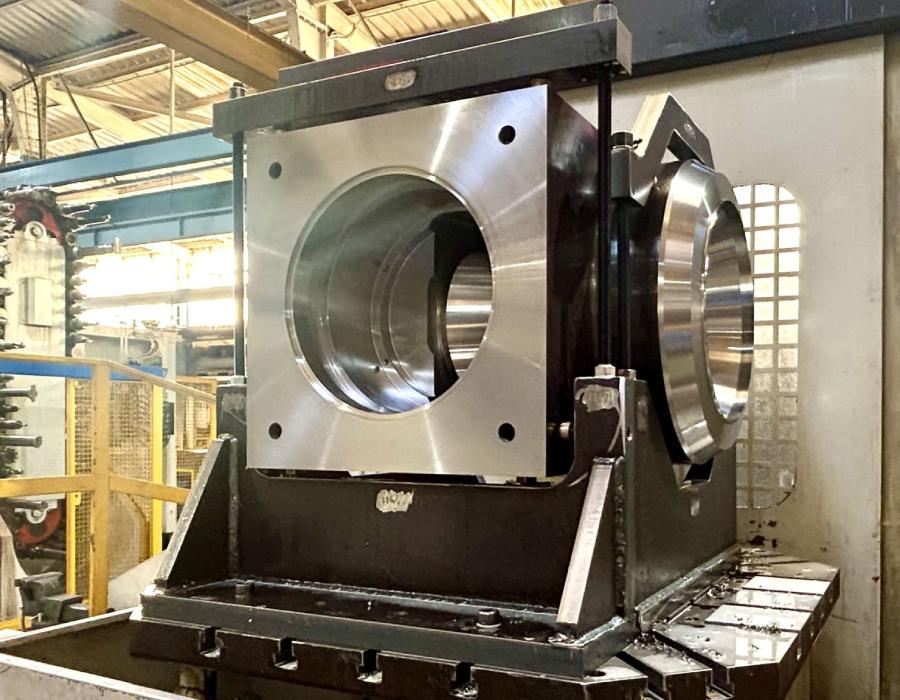

Machining Company: CNC Precision

A machining company is much more than a parts supplier: at Asimer Group it means having a strategic partner that integrates machining production, specialized welding and engineering solutions for critical components of pumps and valves. In industries such as Oil & Gas, cryogenics, naval, water treatment and desalination, precision and on-time delivery determine plant continuity. …