CNC machining of switch plug valves for refineries isn’t about “cutting metal”: it’s about achieving leak-free RTJ sealing, lowering operating torque, and accelerating QA acceptance.

At Asimer Group, we act as a strategic, drawing-based partner for OEMs: we integrate applied engineering, to-drawing machining, QA/NDT, and dimensional control to deliver verified tolerances and traceable documentation aligned with your ITP fewer reworks, fewer delays, more line availability.

What do we solve?

- Hot leaks at RTJ → RTJ 63–125 AARH, flatness and true position; CMM/3D arm verification and checklist.

- High operating torque → Coaxiality ≤ 0.03 mm and concentricity to the plug axis.

- Rework and delays → CMM vs. CAD report + NDT + photos + datum map.

- Distortion → Pre-machining + datums + in-process NDT + controlled finishing.

- Coordination → A single point of contact (engineering + machining + QA + metrology)

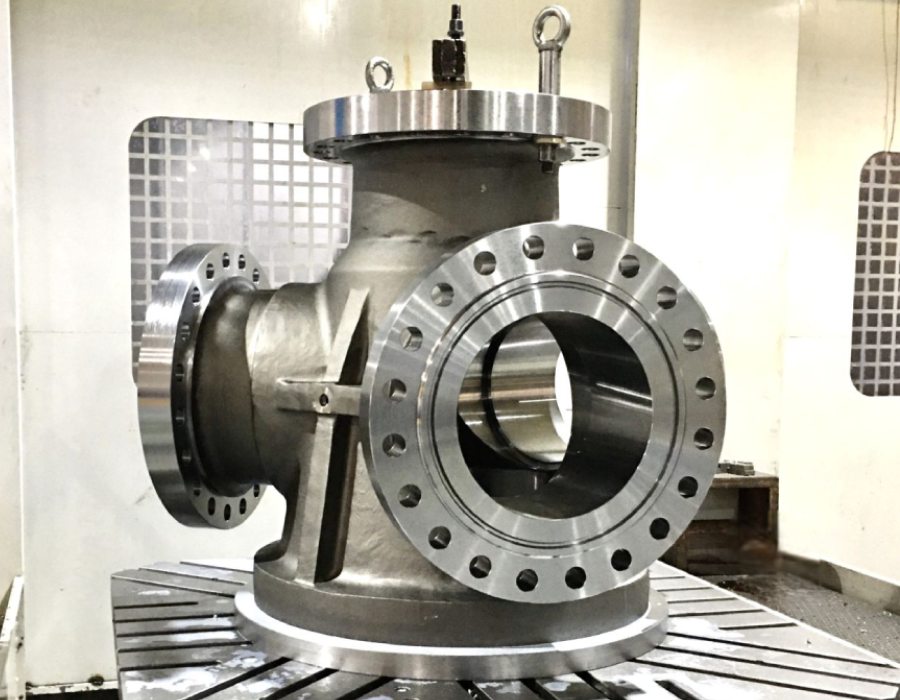

CNC machining of switch plug valves: why it demands tight tolerances

In multi-port (3/4-way) switch valves, the lift-and-turn kinematics only reduce friction if the plug lifts, rotates, and re-seats on surfaces with stable geometry and references; that’s why the drawing sets bore/seat coaxiality to datums at ≤ 0.03 mm, roundness/cylindricity at 0.02–0.04 mm, and Ra 0.8–1.6 μm on lands.

With functional clearances under control, the line of contact is preserved, actuation torque drops, and tightness is maintained after the thermal cycle. To frame these requirements, we start from the valve’s function (operational definition in “What is a valve”) and place the switch valve within the family described in “Types of industrial valves”; from that standpoint it’s clear that GD&T geometric quality referenced to the plug axis and an in-spec RTJ directly condition performance in service (low torque, less wear, fewer leaks).

Material and pressure class in refining: ASTM A217 C12A and CL900 with RTJ

On hot refining lines (furnace circuits, bottoms, vacuum/atmospheric routing), an 18″ CL900 body in ASTM A217 Gr. C12A (9Cr-1Mo) provides the dimensional stability the process requires. Where we make the difference is in how we execute it: RTJ faces per ASME B16.5/B16.47 with 63–125 AARH, flatness ≤ 0.05 mm and verified true position; closure with dimensional control via CMM/3D measuring arm and traceable QA/NDT.

Result: fewer hot leaks, lower actuation torque, and faster QA acceptance in oil refining environments. As a strategic partner, we unify engineering + to-drawing machining + metrology + NDT with deliverables ready for your ITP.

Process sequence in CNC machining of switch plug valves (to drawing)

Pre-machining and datums

We create datums aligned to the plug axis so roughing of the plug bore, seat pockets, and bosses preserves a stable reference; we leave allowances to recover geometry after stress relief.

Where do we add value? This pre-machining is designed to prevent geometric drift in finishing: fewer corrections, fewer stops, and lower torque in lift-and-turn kinematics. For early adjustments before the CMM, we use a 3D measuring arm (portable CMM) as agile in-stock control, so we arrive at finishing with validated datums, shorter times, and clearly reduced rework risk.

In-process NDT

We perform PT and VT to the customer’s procedure and ITP, and we add MT on radii/fillets and bosses when the drawing requires it. These non-destructive tests (NDT) are carried out with full traceability of consumables and equipment, under ISO 9001 and integrated with ISO 3834 when welding is involved.

For liquid penetrant testing (PT), we enforce a rigorous sequence (pre-clean, penetrant, dwell time, removal, drying, developer, and evaluation under visible light or UV-A), recording batch/expiry and equipment. Every indication is located on a datum map and documented with a photo and scale; where applicable, we define disposition (e.g., light deburring, RTJ re-finish, or local re-machining) and close with re-PT.

Value for your operation: reduced hot-leak risk, faster QA acceptance, fewer reworks, and more predictable outage windows.

CNC finishing

Plug/bore geometry 0.02–0.04 mm and coaxiality ≤ 0.03 mm; seats Ra 0.8–1.6 μm and concentricity; RTJ per ASME B16.5/B16.47 with 63–125 AARH, flatness, and true position of the bolt circle. All governed by GD&T referenced to the plug axis. What does your plant gain? Fewer hot leaks, lower actuation torque in lift-and-turn kinematics, and faster QA acceptance. At Asimer Group, as a strategic, drawing-based partner, we integrate CNC Technology in Industry 4.0 environments and, for large diameters, Trevisan centers for stiffness and torque control to ensure series repeatability and more predictable lead times.

Finishing is structured into semi-finish and finish passes with control of spindle/workpiece thermal growth and probing to re-validate datums before the last cut. On RTJs, tangential entry/exit avoids dwell marks; groove and port burrs are treated with controlled deburring to protect sealing lands. The choice of parameters and CNC cutting tool (geometry/coating) is tuned for C12A (9Cr-1Mo), prioritizing process stability and repeatable surface finish—fewer reworks and a faster documentary close-out.

Request RFQ

Verifications and documentation

Final PT + VT; dimensional control with CMM/3D measuring arm (portable CMM) against CAD; interface verification per ASME B16.34. Centralized traceability in the Metrology Room and synchronized with the customer’s ITP: acceptance/rejection criteria per procedure, photographic record of indications (if any), datum map and RTJ checklist (roughness 63–125 AARH, flatness, true position of bolt circle), plus part/heat ID and drawing/CAD revision on the report cover.

What does your plant gain? A clear “as-built dimensional” and orderly NDT evidence that speeds QA acceptance, reduces NCRs and rework, mitigates hot leaks at start-up, and makes outage windows more predictable. As a strategic partner, we deliver a readable, actionable documentation package (cover with project and revision data, control-point index, compliance matrix vs. requirements, technical notes). Each measurement is referenced to its datums and to the instrument (serial/calibration status) for unambiguous reading by your QA. If indications appear, we attach sketches on the datum map, scaled photos, and the agreed disposition (e.g., local re-machining, RTJ re-finish, or re-verification) with closing re-PT.

Dimensional control in CNC machining of switch plug valves: CMM/3D arm as assembly safeguard

Small deviations in coaxiality, concentricity, or total runout translate into torque spikes, premature wear of seat lands, and inter-port leakage; they often stem from ovality, angular misalignment, or clamping-induced clearances. To contain this, we close the metrology loop with CMM (axes, perpendicularities, coaxiality, and total runout) and a 3D measuring arm (portable CMM) (volumetrics, flange positions, and out-of-reach points), comparing each point set against CAD and its datums A/B/C. Result for your plant: fewer NCRs, cleaner assembly, in-range actuation torque at start-up, and faster QA acceptance.

Check lead times and availability:

RTJ and tightness: 63–125 AARH in CL900

The 63–125 AARH band generates the micro-topography that enables controlled gasket bite without tearing and elastic recovery after each thermal cycle. Combined with face flatness/parallelism and groove geometry per ASME B16.5/B16.47, it prevents flange rotation and preload loss that lead to hot leaks. In CL900, tightness arises from a technical triangle of finish, flatness/parallelism, and homogeneous preload verified with profilometry and dimensional control.

Moreover, by concentrating functions in a single switch plug body, manifolds are eliminated, discontinuities decrease, and potential leak points are reduced. To sustain the field result, selection and assembly of fittings in the oil and gas industry must support the sealing strategy: material/metallurgical compatibility, rating (e.g., Class 900), dimensional standard, RTJ compatibility (R/RX/BX), temperature/corrosion conditions, and tightening torque with the gasket and lubricant per the ITP. Direct benefit: fewer hot leaks, faster QA acceptance, and fewer NCRs/reworks at start-up.

Plant outcome: fewer tightness incidents and more predictable outage windows.

Applied engineering and overlay (if shown on the drawing)

If the drawing calls for seat overlay, we assess metallurgical compatibility with C12A (9Cr-1Mo), define the thermal sequence to minimize distortion, and plan re-machining to recover Ra, coaxiality, and GD&T. If it does not apply, we explicitly leave it out of scope. To ensure repeatability, we chain engineering to a clear process route (stock prep, fixturing and datums, in-process control) backed by our Machining Production procedures, and we complete the work in CNC Machining cells where we consolidate fine tolerances and functional finishes before issuing the documentation package.

Value proposition: fewer distortion-driven reworks, protected RTJ tightness, faster QA acceptance, and more predictable outage schedules.

Typical refinery applications (manifold reduction)

In these applications, CNC machining of switch plug valves for refineries ensures controlled coaxiality, RTJ 63–125 AARH, and flange flatness. The effect? Fewer manifolds and branches, fewer potential leak points, and lower actuation torque in lift-and-turn kinematics, with faster QA acceptance.

For product switching and diversion, 3/4-way switch plugs integrate isolation + diversion + combining in a single body, simplifying charge/transfer manifolds, hot-oil/bottoms runs, and product-cut switching under demanding thermal gradients and high cycle counts. Selection guideline: reserve multi-port switching for switch plugs and do not mix it with continuous control or large-diameter on/off at low ΔP; that way you compare performance, pressure drop, and actuation torque in the right context. Direct benefit: fewer NCRs and reworks, fewer flanges/components in the line, and more predictable outage windows.

How we collaborate at Asimer Group

At Asimer Group we act as a strategic, drawing-based partner: a single technical counterpart integrating applied engineering, to-drawing machining, QA/NDT, and dimensional control, aligned with your ITP. We deliver each switch plug body with verified tolerances, in-spec RTJ, and traceable documentation, reducing NCRs and rework, accelerating QA acceptance, and shortening commissioning.

If you manage an installed base of pumps, valves, and compressors, we extend support with predictive maintenance programs (based on machining and specialized welding) for planned seat remanufacturing, recovery of critical surfaces, and dimensional control prior to assembly. Outcome: fewer unplanned stoppages, more predictable schedules, and lower TCO of the assembly. The flow runs on our Machining Production procedures and culminates in CNC Machining cells, ensuring repeatable tolerances and QA-ready deliverables.

FAQs

Can you use values other than ≤ 0.03 mm coaxiality?

We comply with the values on the drawing/specification. In this part, only figures verified from the input are used: ≤ 0.03 mm coaxiality and 0.02–0.04 mm roundness/cylindricity.

Which standards are verified on interfaces and RTJ flanges?

RTJ per ASME B16.5/B16.47 (63–125 AARH, flatness, groove) and interface verification per ASME B16.34, as defined in the ITP.

What QA/NDT scope is included?

PT and VT per procedure and the customer’s ITP; MT when indicated on the drawing. Execution with traceability of consumables/equipment, under an ISO 9001 quality system and integrated with ISO 3834 when welding is involved. Everything is traced in the Metrology Room.

Do you provide dimensional reports?

Yes: CMM/3D measuring arm (portable CMM) vs. CAD with GD&T referenced to the plug axis, NDT records, and an RTJ checklist.