The utility of measuring instruments in the industry lies in their ability to guarantee precise measurements of parameters such as temperature, pressure, dimensions, and the physical and chemical properties of materials. These measurements are essential for interpreting the results of non-destructive testing and making informed decisions about the safety and reliability of components.

In the industrial field, from machining to welding and engineering solutions, having reliable measuring instruments is crucial. These tools allow for precise measurements, ensuring product quality and process efficiency. Accuracy in measurements is essential for achieving consistent results and avoiding waste.

Measuring instruments play a fundamental role in various industries, such as oil and gas, petrochemicals, pulp and paper production, wastewater treatment, naval, cryogenics, and desalination. These instruments are essential for collecting accurate and reliable data that enables monitoring and controlling different variables and processes.

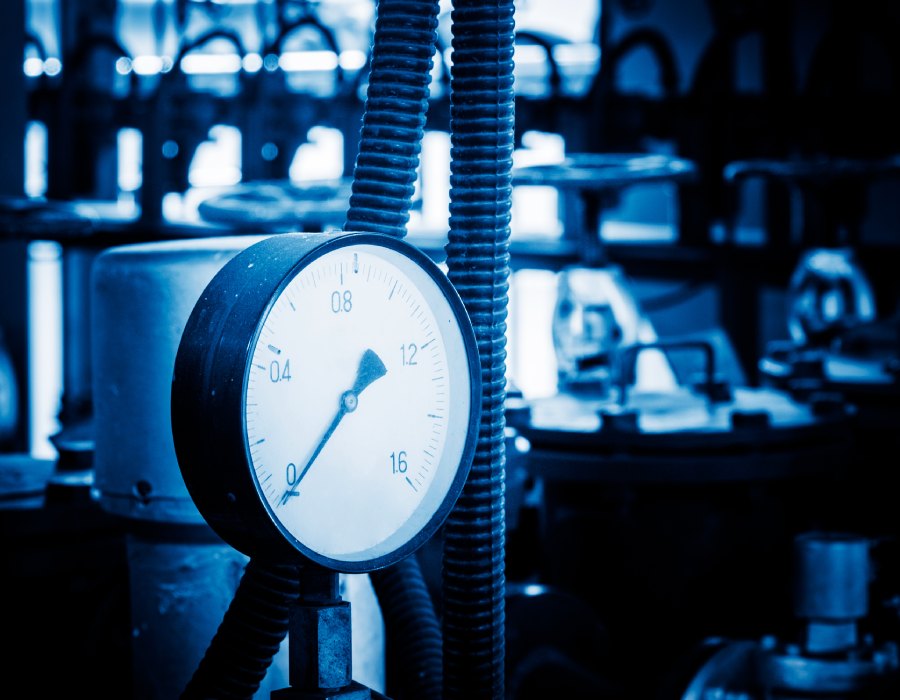

In the oil and gas industry, for example, measuring instruments are used to measure parameters such as pressure, temperature, flow rate, and chemical composition, which are crucial for ensuring safety and efficiency in the exploration, production, and transportation of hydrocarbons. In petrochemicals, measuring instruments are key to controlling the quality of chemical products and ensuring compliance with required standards. In pulp and paper production, they are used to monitor and optimize processes such as cooking and drying, guaranteeing the quality of the final product. In wastewater treatment, measuring instruments allow for the measurement of parameters such as pH, turbidity, and contaminant concentration, helping to ensure that the treated water meets environmental standards. In shipbuilding, these instruments are essential for monitoring different variables, such as fuel level, propulsion system pressure, and engine temperature, thus ensuring the safe and efficient operation of vessels. In the field of cryogenics, measuring instruments are used to monitor and control extremely low temperatures necessary for product preservation and scientific research. And in desalination, measuring instruments are crucial for monitoring the process of transforming seawater into drinking water, ensuring compliance with required quality and salinity standards.

The role of measuring instruments in machining and welding.

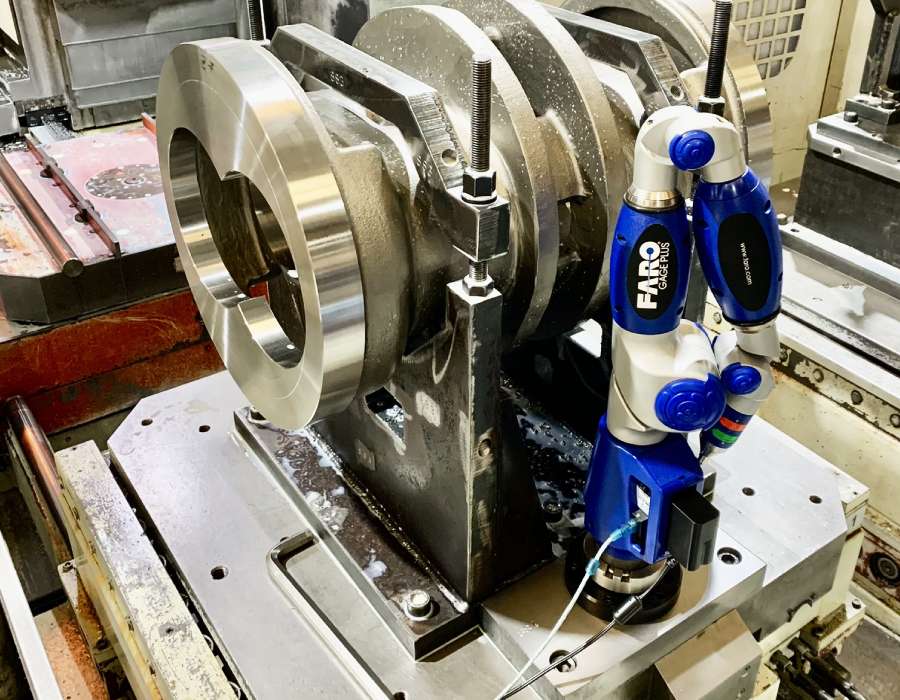

In the industrial sphere, from machining to welding and engineering solutions, having reliable measuring instruments is essential. In the context of Industry 4.0 and the CNC Machining Revolution, measuring instruments play a crucial role in optimizing industrial processes. The integration of advanced measurement technologies in manufacturing, such as 3D metrology systems and laser scanning devices, allows for unprecedented precision in verifying the dimensions and tolerances of produced parts. This not only ensures the quality and consistency of the final product but also maximizes efficiency and reduces costs by identifying early deviations and making real-time adjustments.

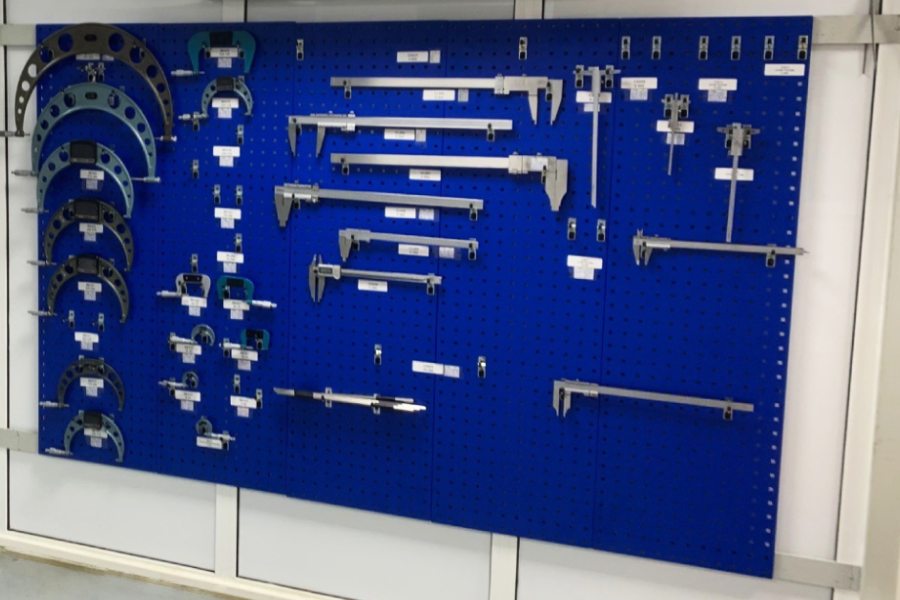

Within this context, it is important to mention that valve testing is a critical aspect in the industry, and measuring instruments play a key role in this process. In the realm of metrology and quality, specialized measuring instruments such as micrometers, calipers, and measurement probes allow professionals to evaluate and verify dimensions, tolerances, and critical characteristics accurately and in detail during machining and welding.

In our article on the “Metrology and Quality Inspection Room,” you can delve into how measuring instruments are used to ensure the accuracy and quality of products in the industry as they are necessary to ensure compliance with standards and specific project requirements.

In metrology and quality, specialized instruments such as micrometers, calipers, and probes evaluate dimensions, tolerances, and critical characteristics in machining and welding processes. When it comes to assessing accuracy in various industrial processes, the use of reliable and precise measuring instruments, such as a coordinate measuring arm, not only ensures the quality of the final product but also contributes to consistency in manufacturing. These devices allow for the identification of any deviations or irregularities in measurements and prompt corrective actions, resulting in high-quality products and greater customer satisfaction.

Moreover, the incorporation of precise measuring instruments in machining and welding helps to prevent costly errors. Early detection of dimensional issues or defects enables adjustments or corrections to be made before they become major failures or premature wear, thus avoiding expensive repairs or product rejections.

Therefore, we could say that measuring instruments are essential elements in the machining and welding of industrial pumps and valves. Their precision, reliability, and ability to ensure quality and accuracy at each stage of manufacturing make them indispensable tools in the industrial sector. By employing these instruments in machining and welding processes, companies can achieve a high level of quality, meet customer expectations, and maintain their competitiveness in the market.

Hence, CNC machining is a process that demands extreme precision, and measuring instruments play a fundamental role in guaranteeing accuracy in this type of manufacturing.

By using a measuring arm, both the quality of the final product and the uniformity in production are ensured.

Benefits of using quality measuring instruments.

The benefits of using quality measuring instruments in industrial processes are essential for achieving high levels of efficiency and performance. Opting for high-quality measuring instruments guarantees a significant improvement in measurement accuracy, leading to a considerable reduction in errors in the processes. This translates into increased reliability and accuracy of the results obtained, which is crucial for making informed and data-driven decisions.

Furthermore, the use of quality measuring instruments ensures the integrity and safety of employees and the work environment. These instruments are designed and manufactured following rigorous standards, minimizing the risk of failures and accidents. With reliable measurements, potential problems can be identified and corrected before they become critical situations, thus improving process efficiency and avoiding costly product rejections or rework. Additionally, high-quality measuring instruments allow for resource optimization by offering greater precision in dosing, inventory control, and material usage. This results in waste reduction and associated costs.

In summary, quality measuring instruments are an essential investment for improving efficiency, safety, and resource optimization in the industry, providing reliable results and facilitating strategic decision-making.

The importance of calibration and maintenance of measuring instruments.

The importance of regular calibration and proper maintenance of measuring instruments in the industry cannot be underestimated. These processes play a fundamental role in ensuring the reliability and accuracy of the obtained results. Regular calibration of instruments ensures that they are properly adjusted and eliminates possible deviations and errors in measurements.

Through regular calibration of instruments, their proper adjustment is guaranteed and possible deviations and errors in measurements are eliminated. This is essential for making informed decisions based on accurate data. Furthermore, proper maintenance of measuring equipment is crucial to ensure their correct functioning over time, avoiding unexpected failures and extending their lifespan. Regular maintenance includes cleaning, periodic calibration, verification of accuracy, and replacement of worn-out parts. By following established calibration and maintenance standards, traceability of measurements and compliance with regulatory requirements are ensured. In conclusion, regular calibration and proper maintenance of measuring instruments are critical aspects to ensure accuracy, reliability, and compliance with standards in the industry.

Engineering solutions integrating measuring instruments.

Current engineering solutions are revolutionizing the industry by integrating advanced measuring instruments into production processes. These solutions go beyond mere automation as they leverage technology to optimize efficiency and productivity. A prominent example can be found in the field of pumps, where measuring instruments are used to monitor and control flow, pressure, and temperature with precision. This allows for real-time parameter adjustments, ensuring optimal operation and minimizing energy consumption.

Similarly, engineering solutions incorporate measuring instruments into valves, enabling precise regulation of fluid and gas flow. This translates into better process management and increased resource efficiency. Another relevant example is the integration of measuring instruments into other industrial components, such as level sensors in storage tanks. These instruments provide real-time information about the quantity of liquid or product present, enabling more efficient inventory management and preventing unnecessary production stops.

Engineering solutions incorporating advanced measuring instruments are key to improving efficiency, precision, and productivity in the industry. From pump and valve control to level monitoring in tanks, these specific applications demonstrate how the integration of measuring instruments in modern engineering drives progress and optimization in industrial processes.

Conclusion.

Asimer Group has its exclusive Metrology Room that performs various key functions. Firstly, measurements are carried out on the most critical dimensions of the projects developed in the corresponding department, specifically regarding valve and pump components. Additionally, it ensures that the most important measuring instruments are maintained in the exact temperature and humidity conditions required. Finally, annual calibrations are conducted for all measuring instruments used in Asimer Group.

In conclusion, measuring instruments play a fundamental role in the industry by ensuring the accuracy, reliability, and efficiency of processes. These tools allow for precise and quantifiable data, facilitating informed decision-making and improving the quality of products and services. High-quality measuring instruments offer benefits such as error reduction, resource optimization, and increased efficiency in industrial processes. Furthermore, adherence to standards and regulations in the calibration and maintenance of instruments ensures traceability and compliance with regulatory requirements. Ultimately, measuring instruments are essential to drive growth and success in today’s industry.