Measuring instruments: What are they and what are they for?

Measuring instruments are much more than “workshop tools”: they are the basis for any decision related to quality, part acceptance, and tolerance compliance. Each caliper, micrometer, or dial indicator is, in practice, the final filter between a conforming component and a potential in-service failure.

When we talk about critical components such as industrial pump or valve bodies, covers, shafts, or impellers, dimensional accuracy stops being a theoretical concept and becomes:

- Less rework.

- Fewer incoming rejections by the OEM.

- Lower risk of leaks, cavitation, or vibrations during operation.

To make this level of accuracy possible, it is not enough to have good measuring equipment: it is essential to combine it with stable CNC machining processes and clearly defined dimensional verification criteria.

In this context, equipment such as Trevisan machining centers and dimensional control systems are directly linked to metrology: the process generates the geometry, and the measuring instruments confirm that this geometry complies with the drawing and applicable standards.

The importance of metrology in industry

Metrology is the science of measurement, and its goal is simple to state but demanding to achieve: obtaining results that are accurate, repeatable, and traceable.

In the manufacturing of components for pumps and valves, this translates into:

- Parts within true tolerance (not “approximately” within tolerance).

- Processes that can be repeated without relying on “operator skill.”

- Documentation that the OEM can audit.

Traditionally, three main branches are distinguished:

- Scientific metrology, which defines standards and units.

- Legal metrology, focused on trade and consumer protection.

- Industrial or applied metrology, the one that actually lives in day-to-day operations: equipment calibration, production control, capability studies, etc.

In Industry 4.0 environments, metrology is no longer a “final checkpoint” but becomes integrated into the process itself: dimensional data feeds decisions on machine adjustments, maintenance, and continuous improvement. This is where the combination of CNC technology and systematic data acquisition truly comes into play.

Metrology at Asimer Group: integration with Industry 4.0 and CNC machining

At Asimer Group, metrology is not understood as an isolated activity, but as a natural extension of machining by material removal and of the process planning itself.

That is why:

- Critical dimensions of machined components are controlled in a climate-controlled metrology room, separated from the production environment.

- Equipment such as portable measuring arms is used to verify complex geometries, alignments, and shapes on pump and valve components.

- Measurement results are directly linked to CNC machining accuracy criteria: if a process starts to drift, dimensional data becomes the first warning signal.

This integration is essential for OEMs that require traceability, dimensional inspection reports, and the ability to adjust designs based on what manufacturing reality is actually showing.

IMEs in machining and welding

In CNC machining, measuring instruments are the link between the OEM drawing and the actual part. Without them, there is no objective way to confirm that an H7 tolerance, a flatness requirement, or a concentricity specification has been met.

A similar situation occurs with TIG welding on pump and valve components:

- After material deposition, functional areas are machined.

- IMEs verify that weld beads, overlays, or repairs have not distorted critical dimensions.

In demanding applications cryogenics, corrosive environments, high pressures dimensional control after welding is just as important as the welding operation itself. That is why the combination of machining + welding + measurement forms an inseparable block.

What is the relationship between measuring instruments and precision machining?

In the field of CNC machining and TIG welding, measuring instruments are essential to ensure accuracy in the manufacture of parts and components. Precision machining, which is fundamental across multiple industrial sectors, requires a high level of dimensional accuracy. Measuring instruments play a crucial role by verifying that machined dimensions meet the required specifications, thereby ensuring the quality of the final products.

TIG welding, as a widely used metal joining technique, also demands a high degree of precision to achieve strong and durable joints. From material preparation to final weld inspection, accurate instruments are needed to ensure that dimensions and tolerances are within specification. Any deviation in dimensions or alignment can compromise the structural integrity of the component, highlighting how sensitive TIG welding is to dimensional accuracy.

Dimensional measurements: direct and indirect

In day-to-day operations, two basic measurement approaches are commonly used:

1. Direct measurement

The dimension of the part is measured directly using the instrument scale (calipers, micrometers, coordinate measuring machines, etc.).

It is fast and flexible, but it requires:

- Proper reading of the instrument.

- Correct contact and pressure techniques.

- Controlled conditions (temperature, surface cleanliness).

2. Indirect measurement

The part is compared against a reference standard (gauge blocks, rings, go/no-go gauges, etc.).

It takes longer to set up, but it is highly reliable when a large number of parts with the same dimension must be controlled.

In both cases, the key criterion is not simply “having the equipment,” but defining a clear measurement strategy: what to measure, with which instrument, how often, and what actions to take when a dimension goes out of tolerance.

Measurement errors: most common types and causes

No measuring instrument is perfect. There is always a difference between the true dimension and the measured value. Understanding where these errors come from is essential to avoid them.

Systematic errors

These are errors that are repeated “in the same direction” due to a specific cause:

- Poorly calibrated instruments.

- Incorrect procedures.

- Working temperatures different from the reference temperature.

This is why periodic calibration and the use of clearly defined procedures are so important. Here, the approach used in non-destructive testing and dimensional verification aligns closely: both require method and discipline, not just equipment.

Random errors

These are caused by small, uncontrollable variations such as vibrations, how the instrument is positioned, or slight temperature changes. They can be reduced through:

- Proper room conditions.

- Operator training.

- Repeating measurements when a dimension is critical.

Errors due to negligence

These are the most dangerous, because they do not depend on the instrument, but on the person using it:

- Misinterpreted readings.

- Use of micrometers or calipers without respecting the correct measuring force.

- Poorly supported parts during measurement.

Continuous training in non-destructive testing methods, measurement techniques, and a deep understanding of the instruments themselves is just as important as purchasing the equipment.

Typical causes: temperature and deformation

Two factors dominate:

- Temperature: both the part and the instrument expand. This is why metrology standards typically reference measurements at 20 °C.

- Material deformation: applying excessive force with a micrometer can deform the part, leading to a measurement of something that will not exist under service conditions.

In sectors where liquid penetrant testing or other inspection techniques are applied, combining dimensional control with NDT provides a much more complete picture: geometry plus material integrity.

Units of measurement and technical terms commonly found in drawings

In production, the basic working unit is the millimetre (mm), but the pump and valve industry is full of Anglo-Saxon legacy standards:

- Nominal diameters in inches.

- Pressures in pounds.

- Design and manufacturing standards of American or British origin.

As a result, it is common for a single drawing to include dimensions in millimetres, references to a specific centrifugal pump, and additional requirements linked to API standards.

Some basic technical terms include:

- Calibration: comparing an instrument against a reference standard to determine its measurement error.

- Levelling and alignment: essential when assembling rotating equipment to avoid vibrations.

- Tolerance: the allowable margin of variation in the manufacture of a part.

All of this ultimately leads to a simple question for the OEM:

“Does this part truly comply with the drawing, or only ‘approximately’?”

Types of measuring instruments in machining

On the shop floor, simple instruments coexist with advanced measuring equipment. Some of the most common include:

- Graduated rulers and tape measures: used for quick measurements, marking, and initial checks.

- Squares, gauges, and templates: used to verify angles, thicknesses, or specific profiles.

- Levels: ensure horizontality or verticality during assembly and alignment operations.

- Calipers (vernier calipers): the universal tool on the shop floor; they measure internal, external, and depth dimensions with good resolution.

- Goniometers: used to measure angles in simple or complex geometries.

- Micrometers: for dimensions requiring hundredths or thousandths of a millimetre, including external, internal, and depth measurements.

- Dial indicators: essential for checking runout, misalignment, or very small dimensional variations.

- Bore gauges: used to verify internal diameters and concentricity in critical housings.

- Measuring machines (CMMs, laser systems, articulated arms, etc.): represent a major step up in capability, enabling full dimensional inspection reports and direct comparisons against 3D models or drawings.

Choosing the right instrument for each dimension—and not trying to measure everything with the same tool is one of the keys to obtaining reliable, meaningful measurement data.

IMEs at Asimer Group: Metrology room, equipment, and traceability

Asimer Group has its own Metrology room where:

- Measurements are made of the most critical product measurements (valve and pump components) that are machined in the Production Department at Asimer.

- Keep the most important IMEs at the required temperature and humidity

- Annual calibrations of all IMEs available at Asimer.

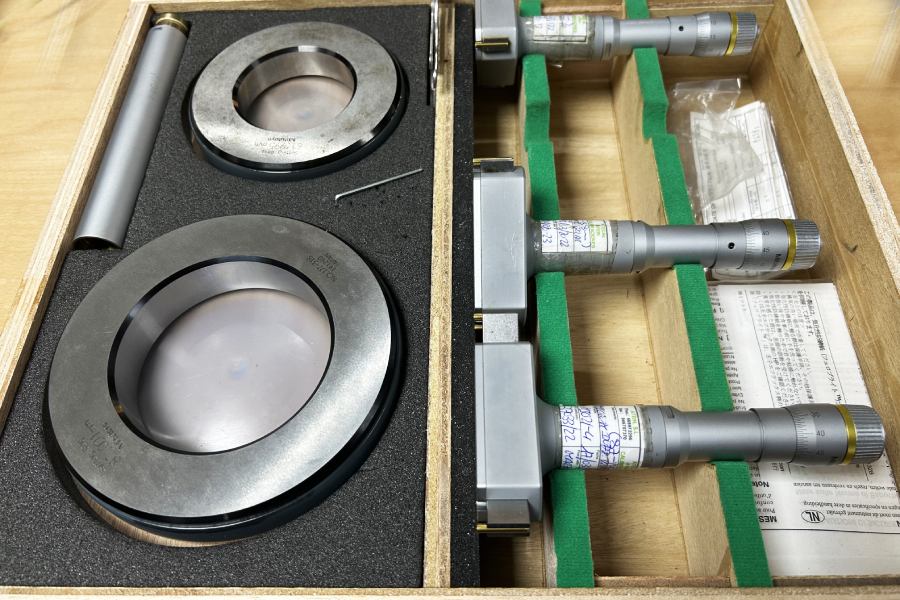

Among the most important IMEs for the control of parts and processes, we can highlight:

- Gauges or foot of king

- External micrometres

- Internal micrometres

- Alexometer

- Durometer

All IMEs in Asimer are kept in a perfect state of conservation in the Metrology room.

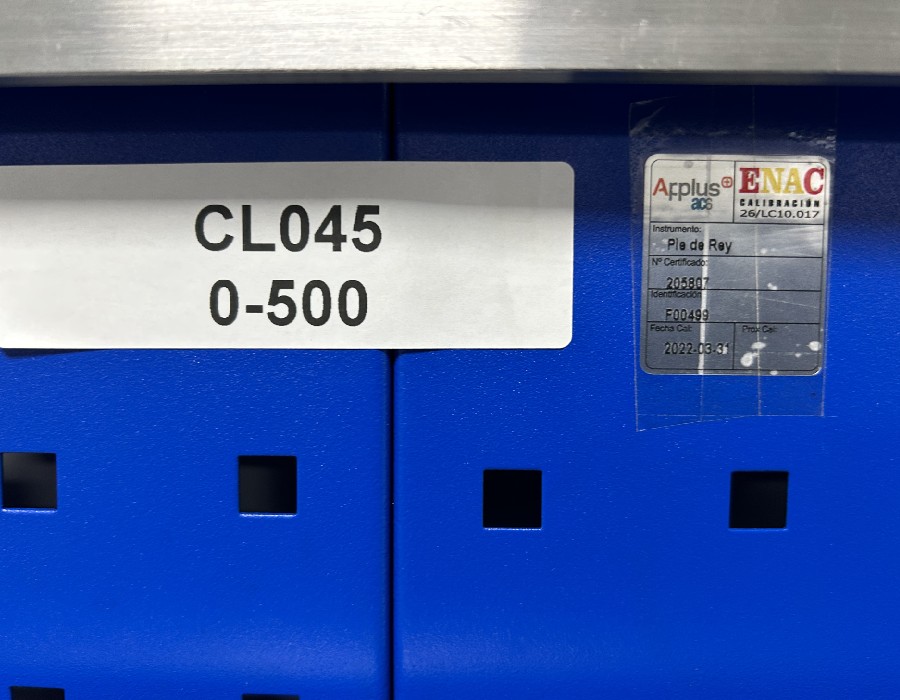

In addition, all IMEs are undergone annual External Calibration by Certified Company according to ENAC Standard, National Accreditation Entity. (The mission of ENAC is to evaluate organisations providing conformity assessment services, such as laboratories, certification and inspection bodies or verifiers, among others. These organisations play a critical role in the safety and well-being of people, the protection of the environment and the improvement of the quality and competitiveness of the products and services offered).

By accrediting ENAC, these evaluators demonstrate that they perform their work according to internationally accepted standards and that they have the required technical competence.

All IMEs are calibrated on the basis of the Calibration Procedures established for this purpose, and with their corresponding identification label, which reflects:

- Instrument and range of measurement

- Serial number

- Date calibration

- Certificate number

- Date next calibration

In addition, measurement results are linked to other control areas, such as non-destructive testing, and to the plant’s own maintenance strategy. In this way, certifications such as

“How certification in non-destructive testing drives industrial quality” stop being just a stamp on paper and become a day-to-day way of working.

How IMEs fit into your value chain

If you are an OEM or a purchasing manager, what really matters to you is not “which micrometer is being used,” but:

- Can I trust that the parts truly comply with the drawing?

- Will I face surprises during assembly or testing?

- Is there traceability for every calibration and every critical measurement?

That is where IMEs, metrology, CNC machining, and well-defined verification processes become a solid argument to:

- Reduce the cost of poor quality.

- Avoid field downtime caused by dimensional errors.

- Support audits and supplier approvals with objective data.

Do you need support in metrology and dimensional control?

If you are evaluating a supplier for machining, welding and checking pump and valve components, the key question is:

Can you show, with data, that you control what you deliver? At Asimer Group, we combine CNC machining, advanced metrology and integration with Industry 4.0 to offer you parts that not only “look good”, but also comply dimensionally and are accompanied by the documentation your projects require

Do you need support in dimensional measurement and verification?

Tell us which components you need to control (bodies, covers, shafts, impellers, trims), which tolerances are required by the OEM, and what documentation you need (dimensional reports, calibrations, inspections). We will respond with a technical, not commercial, approach.

Request measuring instruments & dimensional control assessment