PTA overlay in cryogenic valves is not just a material choice: it is an OPEX decision. Choosing the wrong alloy or designing the overlay poorly can lead to leaks, loss of tightness, unplanned shutdowns and customer claims. Choosing correctly means extending valve service life, reducing interventions and gaining trust as a manufacturer.

In cryogenic environments handling liquefied gases such as LNG, liquid oxygen or liquid nitrogen, overlaid surfaces withstand extreme temperatures, thermal shocks and continuous opening and closing cycles. At Asimer Group we work precisely at this point: designing and executing PTA overlay in cryogenic valves that is fully integrated with machining, metrology and Non-Destructive Testing (NDT) to guarantee tightness and reliability.

Why PTA overlay in cryogenic valves has a direct impact on your OPEX

In a valve for cryogenic service, seat and sealing areas are subjected to:

- Temperatures below −150 °C

- Sudden temperature changes during start-ups and shutdowns

- Mechanical wear due to opening and closing cycles

- Erosion, corrosion and, in some cases, cavitation

If PTA overlay in cryogenic valves is not properly designed (alloy, thickness, joint preparation, welding procedure, post-machining), typical issues appear:

- Microcracks in the overlay due to embrittlement at low temperature

- Lack of adhesion or detachment between base material and overlay

- Premature wear on seating surfaces, with loss of tightness

- Internal or external leaks that force the plant to shut down

In cryogenic pump applications and shut-off and control valves for LNG, these failures mean:

- Loss of valuable product

- Safety risk in the plant

- Increased OPEX due to corrective maintenance and unplanned shutdowns

That is why overlay cannot be treated as a simple “coating”, but as a critical part of the cryogenic valve and of the complete equipment design, within the broader context of cryogenics applications, both in LNG plants and in advanced sectors such as the aerospace industry.

PTA overlay in cryogenic valves with inconel vs stellite: advantages, risks and typical uses

At Asimer Group we regularly work with Inconel® and Stellite® overlays on valves and pumps in severe environments. Each alloy responds to different needs when PTA overlay is applied in cryogenic valves.

Inconel®: Resistance to Corrosion and Low Temperatures

Inconel® overlays (for example Alloy 625) are used when:

- The medium is highly corrosive or aggressive

- Good toughness at low temperature is required

- There are thermal shocks and embrittlement must be avoided

Advantages in cryogenic service:

- Excellent resistance to corrosion and low-temperature cracking

- Good behaviour under thermal cycling

- Compatibility with stainless steels and other common cryogenic alloys

Risks if applied without proper criteria:

- Insufficient thickness that wears out quickly in seating areas

- Poor surface preparation, with risk of porosity or lack of fusion

- Residual stresses if the PTA or TIG welding procedure is not well controlled

Stellite®: Extreme Resistance to Wear and Erosion

Stellite® overlays are selected when:

- The main problem is wear due to friction or erosion

- There is repeated metal-to-metal contact (seats, balls, plugs, discs)

- Very high hardness and wear resistance are required

Advantages:

- Outstanding hardness and wear resistance

- Excellent behaviour in sealing areas subjected to impact and friction

- Protection against erosion and cavitation phenomena

Risks in cryogenic service:

- Differences in the thermal expansion coefficient with the base material that may generate stresses if overlay design is poor

- The need to control heat input and thermal cycles very carefully to avoid cracking

What makes more sense for your projects?

In practice, many manufacturers combine:

- Inconel® in flow paths exposed to the cryogenic fluid and corrosion

- Stellite® on sealing and seating surfaces, where mechanical wear and erosion are critical

The key is not to rely on a generic list of coating types for industrial valves in extreme environments, but to analyse each individual case: process conditions, base material, geometry and tightness requirements throughout the equipment’s service life.

How to design an effective, reliable PTA overlay in cryogenic valves

An effective PTA overlay in cryogenic valves is designed like any other critical component. It is not enough to pick a “catalogue” alloy; design, welding, CNC machining, metrology and Non-Destructive Testing (NDT) all need to be integrated.

Defining critical areas and overlay thicknesses

The first step is to define which surfaces need overlay:

- Seats and sealing surfaces

- Flow paths exposed to aggressive cryogenic flow

- Impact or high-erosion areas

For each zone you must define:

- Overlay alloy (Inconel®, Stellite® or others)

- Minimum and maximum thickness after machining

- Geometrical tolerances and surface finish

This design needs to be aligned with the approach to high-precision machining for cryogenic pump and valve applications, because the overlay must later withstand turning, milling and grinding operations without compromising adhesion or final geometry.

Selecting the process and qualifying procedures

The most common processes for these overlays are:

- PTA welding for overlays with highly controlled deposition, low dilution and good repeatability

- TIG welding for smaller beads, repairs or hard-to-reach areas

A specialised partner provides:

- Qualified WPS and PQR for Inconel® and Stellite® at low temperature

- Welding parameters optimised to limit stresses and avoid cracking

- Control of pre- and post-heating when the base material requires it

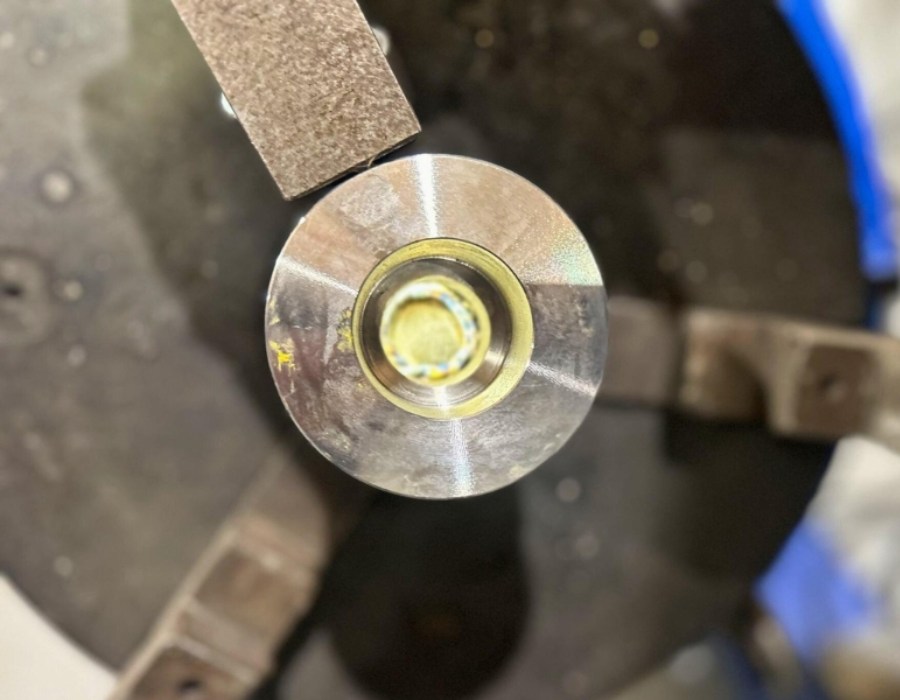

Post-machining and dimensional control

After the overlay, CNC machining comes into play:

- Restoring seat and sealing geometries

- Ensuring concentricity, coaxiality and flatness

- Maintaining the effective overlay thickness in critical areas

The combination of advanced CNC technology with dedicated fixtures for cryogenic bodies and components allows you to keep very tight tolerances on the overlay without compromising adhesion or effective thickness. In this way, machining becomes an ally of PTA overlay, not an additional source of stresses or defects.

This is where it makes sense to work with a provider that combines overlays and machining of cryogenic bodies and components within the same workflow, to avoid coordination issues between different shops.

Metrology and non-destructive testing

The final stage goes through the metrology room and Non-Destructive Testing:

- Complete dimensional verification of overlaid surfaces

- PT/VT/MT/UT testing according to project requirements

- Records and traceability by serial number, batch and applied procedure

In cryogenic service, a small defect in the overlay can grow over time due to thermal stresses and turn a microcrack into a leak. That is why inspection is not an “extra”, it is part of the overlay design.

In many cryogenic projects, liquid penetrant testing is the first filter for detecting surface cracks in overlaid areas before moving on to more advanced NDT. Integrating this type of inspection within the overlay + machining workflow makes it possible to catch defects early and prevent a microcrack from becoming a leak during commissioning or operation.

PTA overlay in cryogenic valves within your plant’s cryogenics cluster

Metallic overlays for cryogenic service cannot be analysed in isolation. They are part of a broader strategy that includes:

- Selection of base material (stainless steels, SuperDuplex, nickel-based alloys)

- Design of pumps and valves for cryogenics applications

- Maintenance and spare-parts strategy

Content that already explains cryogenic valves and cryogenic pump applications helps to understand where these overlays work. PTA overlay in cryogenic valves acts as an additional “insurance” against wear, erosion and corrosion, provided it has been designed consistently with the rest of the system.

Checklist for choosing a PTA overlay provider for cryogenic valves

This checklist is intended for technical purchasing and engineering departments that want to reduce risk when outsourcing overlays:

Proven experience in cryogenic projects

- References in LNG and other cryogenic applications

- Real cases of overlays on valves and pumps for cryogenic service

Advanced welding capability

- Proven know-how in PTA welding and TIG welding on nickel- and cobalt-based alloys

- WPS/PQR qualified for low temperature and successfully audited

Integration with machining and metrology

- Ability to perform overlay and CNC machining in the same workflow

- Metrology room equipped to check complex geometries after overlay

Quality and traceability

- Clear inspection plans, including NDT when required

- Traceability of material, welding parameters and measurements associated with each part

OPEX-focused, not just price-per-part

- Ability to discuss service life, maintenance intervals and total cost of ownership

- Improvement proposals based on field experience, not just datasheets

A provider that meets these points becomes a trusted technical partner for your cryogenic equipment.

How Asimer Group supports you with PTA overlay in cryogenic valves

At Asimer Group we work as a technology partner for pump and valve manufacturers operating in extreme conditions. In the field of PTA overlay in cryogenic valves, we provide:

- Real experience with overlays in Inconel®, Stellite® and other special alloys for cryogenics, Oil & Gas and high-risk processes

- Integration of PTA welding, TIG welding and CNC machining in the same facility, reducing lead times and avoiding coordination problems

- High-precision machining capabilities for cryogenic pump and valve applications, allowing us to treat the overlay as part of the whole assembly, not as an isolated operation

- Metrology room and Non-Destructive Testing infrastructure to close the quality loop with dimensional and inspection reports aligned with each project’s requirements

For OEMs and purchasing departments, this translates into fewer leaks, fewer corrective interventions and greater reliability in the field.

This entire approach is supported by the CNC machining applications we develop every day in valve bodies, internal components and pumping elements for demanding sectors. This allows us to treat PTA overlay not as an isolated operation, but as one more stage within a fully integrated manufacturing and repair workflow for industrial pumps and valves.

Reviewing your overlays in cryogenic service: next step

If you are evaluating new overlay designs with Inconel® or Stellite® for cryogenic pumps and valves, or you are already experiencing leaks or premature wear in service, now is the right time to review design, materials and process together with a specialised partner.

Below you will find a direct contact button to reach the Asimer Group team.

Do you want to review your Inconel® / Stellite® overlays in cryogenic service?

Tell us what type of cryogenic pumps and valves you manufacture and what issues you are seeing on your seating and sealing areas. We will analyse alloy selection, the PTA/TIG overlay process and post-machining with you to reduce leaks, wear and unplanned shutdowns.

Talk to the Asimer Group team