Liquid penetrant testing is one of the most widely used non-destructive testing methods for controlling the surface quality of metallic and non-metallic components without damaging the part. In the context of industrial pump and valve manufacturers, liquid penetrant testing on critical industrial components is used to ensure that casings, covers, impellers, shafts, and sealing areas leave production free from cracks or surface-breaking discontinuities that could lead to leaks, unplanned downtime, or quality claims.

In addition, this type of inspection is increasingly integrated with CNC machining and TIG welding on components subjected to pressure, thermal fatigue, or aggressive environments (cryogenics, oil refining, desalination, water treatment, etc.), where a minor surface defect can escalate into a major in-service issue.

For pump and valve manufacturers, integrating liquid penetrant testing within machining and welding processes helps reduce downstream risk and supports consistent surface quality in critical components.

What are liquid penetrants?

Liquid penetrants are products formulated with low surface tension and high wettability, allowing them to enter surface-opening discontinuities by capillary action, such as cracks, pores, fissures, lack of fusion in welds, or open laminations. After the appropriate penetration time, excess penetrant is removed and a developer draws out the penetrant retained in the defects, making them visible as clear, high-contrast indications.

From a metrology and quality-control perspective, liquid penetrant testing is a simple, cost-effective, and highly sensitive inspection method, complementing both direct visual inspection and other non-destructive testing techniques with greater technical complexity, such as ultrasonic testing or industrial radiography.

Definition and purpose

The objective of liquid penetrant testing is twofold:

- To detect surface defects that are not visible to the naked eye.

- To document that the component has passed a surface quality inspection in accordance with a defined procedure.

For manufacturers working with tight tolerances and complex geometries such as impellers, valve bodies, or sealing elements liquid penetrant testing is integrated into quality plans alongside CNC machining accuracy, dimensional control using measuring arms, and final verification in the metrology room.

History and evolution

Liquid penetrant testing began to be used systematically in the mid-20th century as an evolution of the traditional “oil and chalk” method. Since then, it has been standardized within non-destructive testing codes and standards and has evolved toward safer, less aggressive formulations compatible with a wide range of materials and service temperatures.

Today, it is routinely applied in sectors such as oil and gas, naval engineering, petrochemical processing, cryogenics, and desalination, where the integrity of welded joints and machined components is critical to sealing performance and operational safety.

Liquid penetrant inspection process

Liquid penetrant inspection is a standardized process composed of several clearly defined stages. A well-designed procedure is just as important as the penetrant product itself.

Before starting, it is often combined with other control activities, such as dimensional verification using CNC machining tools, visual inspections in accordance with applicable standards, or even other non-destructive testing methods when the component requires it.

For manufacturers of pumps and valves, applying a controlled and well-defined penetrant inspection process helps ensure consistent surface quality before components move to final assembly or delivery.

Step 1: Surface preparation

The surface must be clean, dry, and free from grease, paint, rust, or chips resulting from machining by material removal. Any contaminant can mask a real defect or generate false indications. At this stage, degreasers, light mechanical cleaning, or controlled blasting are used, depending on the material and the criticality of the component.

Step 2: Application of the liquid penetrant

The penetrant is applied by immersion, spraying, or brushing, ensuring uniform coverage over all critical areas: TIG weld beads, transition zones, threads, chamfers, bolted joints, etc. Poor application can leave areas uninspected.

Step 3: Penetration time

The penetration time is defined in the procedure and depends on the type of penetrant, temperature, and material. It is essential not to fall short (defects are not fully filled with penetrant) or exceed it (risk of drying or the product flowing out of the defect).

Step 4: Removal of excess penetrant

Once the penetration time has elapsed, excess penetrant is carefully removed from the surface without “washing out” the penetrant retained in the discontinuities. This can be done using water, solvent-dampened cloths, or specific techniques depending on the type of penetrant (water-washable, post-emulsifiable, etc.).

Step 5: Application of the developer

The developer acts like a sponge: it absorbs the penetrant trapped in defects and draws it back to the surface, creating visible indications. This is where the inspector’s experience makes the difference, allowing them to distinguish between relevant and false indications based on shape, size, and location.

Step 6: Inspection and interpretation

Interpretation is carried out under appropriate lighting conditions (white light or UV, depending on the type of penetrant). At this stage, indications are recorded, photographs are taken if necessary, and a decision is made on whether the component is acceptable or requires repair, CNC re-machining, or a new weld for corrosive environments, for example.

Applications of liquid penetrant testing

Industries using liquid penetrant tests

Liquid penetrant tests are used in various industries, including:

Aerospace

In the aerospace industry, the safety and reliability of components are crucial due to operational and safety demands. Liquid penetrant tests are used to inspect a variety of critical parts:

- Critical Components:

Wings, fuselages, and landing gear are essential parts of an aircraft that require regular inspection to detect cracks or defects that could compromise their performance and safety. Penetrant inspections can reveal micro-cracks in the material that could be dangerous if not detected in time.

- Welds:

Welds in structural components of aircraft undergo significant stress during flight. Liquid penetrant tests help identify defects such as surface cracks or lack of fusion in welded areas, ensuring structural integrity is maintained.

- Repairs and Maintenance:

During aircraft repairs or maintenance, liquid penetrant tests allow for quick and effective evaluation of repaired surfaces, ensuring the repairs are correctly done and free of hidden defects.

Automotive

In the automotive industry, liquid penetrant tests are used to ensure the quality and safety of a wide range of components:

- Engine Parts:

Critical engine components such as cylinder blocks, heads, and cast aluminum parts are inspected to detect cracks or defects that could affect engine performance or cause failures. Early detection of these defects can prevent catastrophic engine failures.

- Chassis and Structural Components:

The chassis structures and other vehicle parts are subjected to constant loads and stresses. Liquid penetrant tests are used to identify defects in welds, joints, and structural metal parts that could compromise vehicle safety.

- Body Repairs:

Damaged and repaired vehicles are also inspected to ensure the repairs have not left surface defects that could weaken the body integrity.

Construction

In construction, liquid penetrant tests are applied to verify the quality and safety of structural elements:

- Metal Structures:

Steel structures used in buildings, bridges, and other constructions are subjected to heavy loads. Liquid penetrant tests are used to detect surface defects in beams, columns, and other metal pieces, helping to prevent structural failures.

- Welds:

Welds in metal structures and construction elements must be inspected to ensure they are free of cracks and defects. Liquid penetrant tests allow for accurate evaluation of weld quality.

- Bridges and Other Infrastructure:

Bridges and other infrastructures require regular inspections to ensure their safety.Liquid penetrant tests are a useful tool for detecting defects in steel and other construction materials.

Manufacturing

In manufacturing, liquid penetrants tests are used to ensure the quality and reliability of produced parts:

- Metal Parts:

During the manufacturing process of metal parts, liquid penetrants tests are applied to detect surface defects such as cracks, porosity, and other issues that could affect part performance. This is crucial to ensure parts meet quality standards.

- Plastic Parts:

Although less common, liquid penetrant tests can also be used on certain plastic parts to detect surface defects that could affect functionality. This is especially relevant for high-performance components that must meet strict specifications.

- Quality Control:

The use of liquid penetrant tests in quality control during and after manufacturing helps identify and correct defects before parts are shipped to the customer, reducing the risk of product failures.

Cryogenics

In the cryogenic industry, liquid penetrant tests are used to inspect equipment and components operating at low temperatures, ensuring structural integrity and the absence of defects that could cause failures in extreme conditions.

- Cryogenic Components:

Storage tanks and pipelines transporting liquefied gases such as nitrogen and oxygen require regular inspection to detect cracks or defects that could compromise their performance and safety. Penetrant inspections can reveal micro-cracks in the material that could be dangerous if not detected in time.

- Valves and Pumps:

Valves and pumps in cryogenic systems are subjected to extreme conditions that can cause surface cracks or corrosion. Liquid penetrant tests help identify these defects, ensuring equipment functions safely and efficiently.

- Refrigeration Equipment:

During the maintenance of cryogenic refrigeration equipment, liquid penetrant tests allow for quick and effective evaluation of surfaces, ensuring no hidden defects that could affect performance.

Oil and Gas

In the oil & gas industry, liquid penetrant tests are essential for inspecting pipelines, storage tanks, and drilling components, detecting surface defects that could lead to leaks or catastrophic failures.

- Transport Pipelines:

Pipelines transporting oil and gas are subjected to severe pressures and environmental conditions. Liquid penetrant tests are used to detect cracks and corrosion in pipelines, preventing leaks and potential accidents.

- Storage Tanks:

Storage tanks for oil and chemicals require regular inspection to detect surface defects that could cause spills. Liquid penetrant tests allow for accurate evaluation of tank integrity.

- Drilling Equipment:

Drilling components such as bits and heads are exposed to extreme stresses. Liquid penetrants tests help identify cracks and other surface defects that could cause failures during drilling operations.

Petrochemical

In the petrochemical industry, liquid penetrant tests are applied to inspect processing equipment, pipelines, and pressure vessels, helping detect surface defects that could lead to leaks of hazardous substances or operational failures.

- Pressure Vessels:

Pressure vessels used in petrochemical processes must be inspected regularly to detect cracks and other defects that could compromise their safety. Liquid penetrant tests allow for early detection of these problems.

- Pipes and Ducts:

Pipes and ducts transporting chemicals need detailed inspections to ensure there is no corrosion or cracks that could cause leaks. Liquid penetrant tests are an effective tool for these inspections.

- Processing Equipment:

Reactors and distillation columns in petrochemical plants require precise surface evaluation to detect any defects that could affect the process. Liquid penetrant tests help ensure the quality and safety of this equipment.

Desalination

In desalination plants, liquid penetrant tests are applied to verify the quality and safety of structural elements, ensuring there are no surface defects that could affect operation and the quality of treated water.

- Saltwater Pipes:

Pipes transporting saltwater to the desalination plant are subject to corrosion and wear. Liquid penetrant tests help detect these problems before they cause system failures.

- Storage Tanks:

Tanks storing desalinated water need regular inspections to ensure there are no surface defects that could contaminate the treated water. Liquid penetrant tests allow for detailed evaluation of these tanks.

Processing Equipment:

Critical components of the desalination process, such as reverse osmosis membranes, require thorough inspection to ensure there are no cracks or damages that could affect their functionality. Liquid penetrant tests are ideal for these evaluations.

Naval

In the naval sector, liquid penetrant tests are used to inspect hulls, propellers, and other components, identifying surface defects that could affect vessel performance and safety.

- Ship Hulls:

Ship hulls are constantly exposed to adverse conditions, which can lead to cracks and corrosion. Penetrant testing allows for detailed inspection of the hull surface to detect these defects.

- Structural Welds:

Welds in the ship’s structure must be inspected to ensure they are free from cracks and defects. Penetrant testing offers precise evaluation of the quality of these welds.

- Mechanical Components:

Mechanical components, such as propellers and rudders, require inspection to detect any surface defects that could affect the vessel’s performance and safety. Penetrant testing is an effective tool for these inspections.

Water Treatment

In water treatment and desalination plants, this method is used to inspect pipes, tanks, and processing equipment, ensuring there are no surface defects that could affect operation and the quality of treated water.

- Water Pipes:

Pipes that transport water throughout the plant are subject to wear and corrosion. Penetrant testing helps identify these problems in a timely manner, ensuring safe and efficient operation.

- Storage Tanks:

Tanks that store treated water must be regularly inspected to ensure there are no surface defects that could compromise the water quality. Penetrant testing allows for a detailed evaluation of these tanks.

- Processing Equipment:

Filters, pumps, and other processing equipment need thorough inspection to detect cracks and other surface defects. Penetrant testing is ideal for these evaluations, ensuring the proper functioning of the water treatment system.

Pulp and Paper

In the pulp and paper industry, penetrant testing is used to ensure the quality and safety of equipment and products, detecting surface defects that could affect the performance and integrity of produced items.

- Paper Machines:

Paper machines, such as cylinders and rollers, are subject to constant wear. Penetrant testing allows for the detection of cracks and other surface defects that could affect the quality of the produced paper.

- Processing Equipment:

During the pulp and paper manufacturing process, penetrant testing is applied to detect surface defects in processing equipment, ensuring there are no issues that could compromise process efficiency.

- Pipes and Tanks:

Pipes and tanks used in the pulp and paper processing need regular inspections to detect corrosion and other defects. Penetrant testing allows for detailed evaluation of these components, ensuring their integrity and functionality.

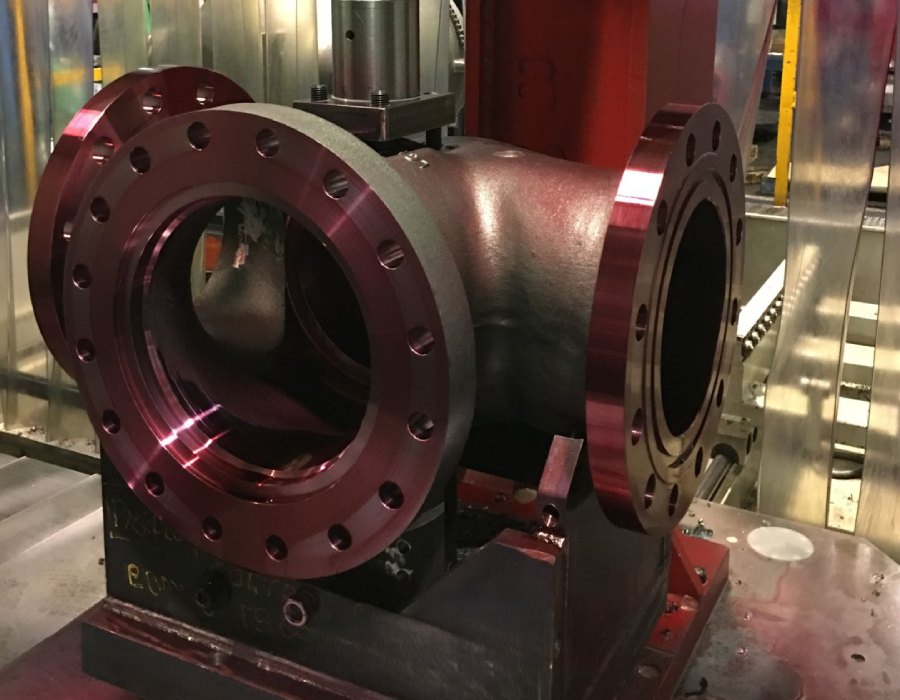

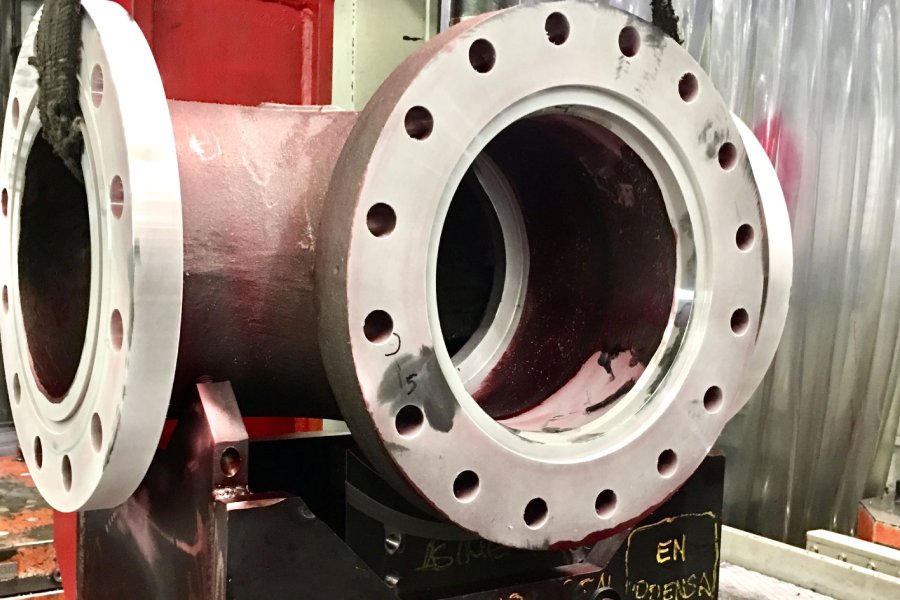

At Asimer Group, liquid penetrant testing is particularly applied to:

- Casings, covers, and key components of centrifugal pumps.

- Components of cryogenic valves and large-size valves.

- Equipment subjected to pressure and temperature cycles in oil refining applications.

- Sealing elements and transition areas in cryogenic applications and industrial applications of centrifugal pumps.

In these applications, surface integrity is critical to ensuring tightness, reliability, and long-term performance under demanding operating conditions.

In many cases, liquid penetrant testing forms part of a machining-based predictive maintenance approach for pumps and valves, together with dimensional inspection, balancing, and other condition-monitoring techniques applied to critical components.

Types of detectable defects

This method is particularly effective for detecting:

- Fatigue cracks in shafts, casings, and high-stress areas.

- Porosity and lack of fusion in TIG or MIG weld beads.

- Cracks around threads, chamfers, and section changes.

- Surface defects in machined areas after finishing operations.

When combined with proper material selection and coating types for industrial valves operating in extreme environments, liquid penetrant testing helps close the loop between design, manufacturing, and quality control.

Advantages and limitations of liquid penetrant testing

Advantages

- A relatively cost-effective and quick-to-implement inspection method.

- High sensitivity to very fine surface defects.

- Applicable to a wide range of non-porous materials.

- Ideal for integration into production lines where non-destructive testing is already performed routinely.

For pump and valve OEMs, integrating liquid penetrant testing into the quality plan for industrial pumps and valves helps reduce leaks and unplanned downtime while providing objective inspection documentation.

Limitations

- Is sensitive to environmental conditions (temperature, humidity, air currents).

- Does not detect internal or subsurface defects.

- Requires very careful surface preparation.

- Generates waste that must be properly managed.

Comparison with other non-destructive testing methods

Compared to other non-destructive testing techniques, liquid penetrant testing has a clearly defined role:

- Compared to radiography: it does not inspect internal defects, but it is simpler, safer, and more cost-effective.

- Compared to ultrasonic testing: it does not require couplants or complex signal interpretation, but it is limited to surface defects.

- Compared to magnetic particle testing: it can be applied to non-ferromagnetic materials and more complex geometries.

For this reason, liquid penetrant testing is commonly combined with other inspection techniques within a comprehensive non-destructive testing plan for critical equipment, especially in sectors that use large-size valves or pumps operating under high pressure.

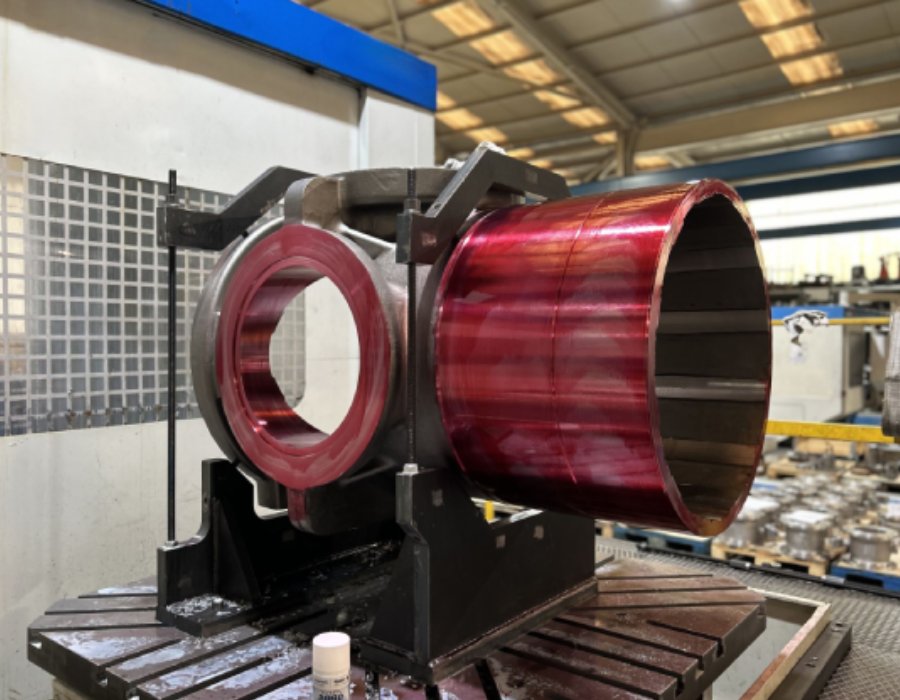

Liquid penetrant testing at Asimer Group

At Asimer Group, liquid penetrant testing is not considered a standalone service, but part of a 360° industrial solution that integrates:

- High-precision machining for the oil & gas sector and other industrial applications.

- Machining of pumps and valves in stainless steel and special materials.

- TIG welding and automatic MIG welding processes adapted to corrosive environments.

- Dimensional control using measuring arms and metrology room equipment.

- Complementary verification using other non-destructive testing methods when required by the project.

When pump, valve, or compressor manufacturers outsource these phases to Asimer Group, they rely on a single partner capable of machining, welding, coating, measuring, and verifying components using liquid penetrant testing and other techniques, reducing the number of suppliers and potential failure points.

Do you need liquid penetrant inspection for industrial pump and valve components?

Tell us the type of equipment (pump, valve, compressor), material, and industry (oil & gas, cryogenics, naval, petrochemical…), and whether you require liquid penetrant testing only or a complete service including machining, welding, and dimensional control. We will respond with a technical proposal focused on reliability and the reduction of unplanned downtime.

Request an inspection assessmentLiquid penetrant testing within the quality Plan for Industrial pumps and valves

Liquid penetrant testing remains one of the most effective and cost-efficient tools for surface quality control in industrial components. When integrated into a workflow that includes CNC machining, specialized welding, and non-destructive testing, it enables the early detection of defects that would otherwise appear once the pump or valve is already assembled and in service.

For manufacturers working with tight tolerances, aggressive media, or critical equipment such as cryogenic valves, pumps for cryogenic applications, or components subjected to welding for corrosive environments a well-defined liquid penetrant inspection procedure adds an additional layer of safety, resulting in fewer leaks, reduced unplanned downtime, and greater confidence from the end customer.

For OEMs seeking to strengthen their quality plans, integrating liquid penetrant testing alongside machining and welding processes supports more reliable components throughout the entire lifecycle.