Machining and welding for the petrochemical industry

Machining and welding for the petrochemical industry

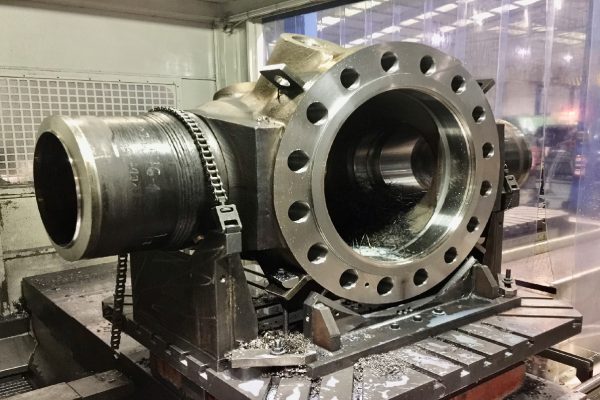

Machining and welding for the petrochemical industry demand precision and coordination from the very first drawing. We restore tolerances on valves and pumps that cannot be allowed to fail, apply localized weld overlays (Inconel 625, Stellite), and finish with dimensional inspection in our metrology room. We coordinate QA/NDT, generate a complete documentation dossier, and deliver equipment ready for a leak-tight start-up, with no leaks and no last-minute

What we deliver to drawing: precision, overlays and verification

What we deliver to drawing: precision, overlays and verification

- Machining of critical components: bodies, bonnets, plugs/obturators, seats and flanges (RF/RTJ); roughness and parallelism control, and CMM verification. We integrate CAD/CAM to ensure repeatability in short-run series according to drawing.

- Welding and overlays (cladding): selective application of Inconel 625 and Stellite in wear/corrosion areas; TIG/MIG joints and PTA processes with qualified WPS/PQR and hardness/bonding control.

- QA/NDT and tightness: we define the inspection plan, verify in the metrology room and carry out non-destructive testing; we also control leak-tightness on RTJ/RF surfaces and perform pressure tests prior to final assembly. We deliver a dossier with dimensions, weld bead maps and hardness readings for audit purposes.

Our expertise

Since its beginnings, Asimer Group has always been involved in major projects in the chemical and petrochemical sector, whether with products requiring special overlays (Stellite and/or Inconel 625 cladding) or with the machining of demanding valve components.

Butterfly Valve Discs 42” 300# (CF8M)

Pre-machining + Stellite Gr.6 hardfacing + final machining + NDTs. Build-to-print project for 6 butterfly valve discs 42” 300# (CF8M) for chemical/petrochemical (downstream) applications. Sequence: pre-machining; PT before overlay; hardfacing with Stellite Gr.6 (WPS & PQR acc. ASME; ISO 3834-2); final machining; final NDTs (PT/VT by Level II operators).

Triple Offset Butterfly Valves DN500 PN16 / CL150 (WCB)

Pre-machining + PT + Stellite Gr.6 hardfacing + final machining + final inspection. Build-to-print project for triple offset butterfly valves DN500 PN16 / CL150 (WCB) for chemical/petrochemical (downstream) service. Sequence: pre-machining; PT on sealing areas (Level II); hardfacing with Stellite Gr.6 (WPS & PQR / ASME; ISO 3834-2); final machining; final inspection (PT/VT) on all machined surfaces.

Gate Valve Bodies DN125 CL900 BW (A316L)

3.2 certification + pre-machining + PT + final machining + NDTs (HT/PT/VT). Build-to-print project for 12 gate valve bodies DN125 CL900 BW in A316L, destined for a chemical plant in the Netherlands (chemical/petrochemical — downstream — application). Scope: supply of the block (320×280×500) in A316L with 3.2 certificates; pre-machining; PT on sealing areas; final machining; final NDTs (hardness, PT and VT, performed by Level II operators).

Engineering solutions

for the petrochemical industry

Engineering solutions

for the petrochemical industry

Related products

Top entry ball valve 24" 1500# WCB Inconel