Machining company: Solutions for industry

At Asimer Group, we take pride in being a machining company specialized in precision solutions for various industrial sectors. Our expertise, advanced CNC technology, and commitment to quality allow us to deliver high-level products and services to national and international customers.

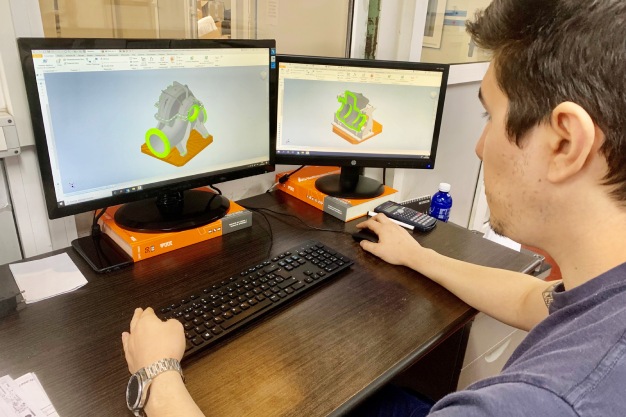

The best professionals in industrial machining

Our team consists of specialists in CNC machining and advanced manufacturing processes. We have engineers with expertise in design and optimization of industrial components, ensuring that every project meets the highest quality standards. Continuous training allows our team to apply the latest innovations in manufacturing.

Lean Manufacturing: efficiency in our processes

We apply Lean Manufacturing methodologies to maximize efficiency and minimize waste in every production process. Our approach allows us to offer optimized lead times and competitive costs without compromising the quality of the final product. Thanks to this philosophy, our customers receive machined components with the best balance between precision and cost-effectiveness.

Advanced technology

in

machining

At Asimer Group, we rely on technology as the foundation of our production process. We have:

- 5-axis CNC machining centers, capable of performing complex cutting and milling operations with micrometric tolerances.

- High-precision CNC lathes, designed for manufacturing cylindrical components with demanding details.

- Advanced CAD/CAM software, optimizing machine programming to achieve maximum efficiency.

Optimized

delivery

time

We use advanced planning software that enables precise production scheduling, preventing delays and ensuring orders are delivered on time. This methodology allows us to adapt to urgent projects without compromising quality.

24/7 shift

hours

We operate with extended 24/7 shifts, allowing us to maintain continuous production and respond quickly to unforeseen events or urgent requests. Thanks to the automation of our equipment, we ensure a seamless and efficient service for our clients.

Especialized

team

Each of our professionals is trained in the most advanced machining techniques. Our team consists of specialists in manufacturing, quality control, and production engineering, allowing us to develop customized solutions tailored to our clients’ needs.

Commitment to Quality

We guarantee the highest quality in all our components through strict controls at every stage of the machining process. Each part is measured using high-precision metrology equipment, ensuring it meets the dimensional and functional requirements demanded by our clients.

Professional machining company

We keep our facilities in optimal condition to ensure an organized production process for our components. We pay special attention to cleanliness and order in the workspace, creating an environment that instills confidence in our clients throughout the entire process.

Certifications that support our work

How do we guarantee quality?

In our processes, we conduct all necessary verifications required for each project, defining them in the specific control plan for each reference. In addition to these checks, we carry out a final inspection before dispatching the product.

We have a highly precise and well-defined quality control system, ensuring full traceability of each product throughout the entire value chain from raw materials to treatments and final processing.

All documentation is properly recorded and available to our customers upon request, including material certificates, treatment certifications, and more.

- ISO 9001:2015 – Quality management systems.

- ISO 3834-2 – Quality requirements for fusion welding of metallic materials.

- Compliance with international safety and quality standards, ensuring excellence in every process.

Our machining services

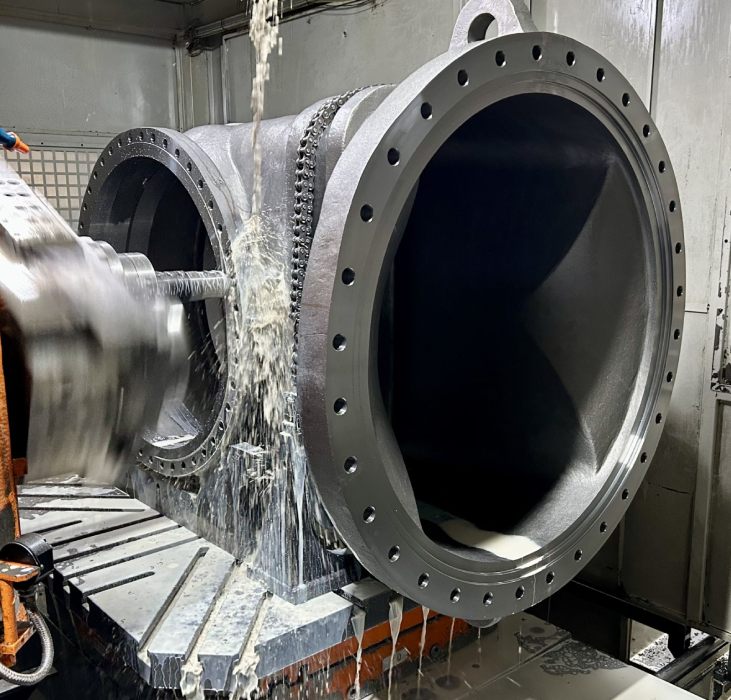

Industrial machining

We provide our customers with a high-quality service, supported by machining centers and CNC lathes specialized in each of our processes. We study your needs and offer you tailored solutions.

Our machining facility is equipped with cutting-edge technology and precision machinery, allowing us to work with a wide variety of materials, including:

- Steels, stainless steels, duplex, superduplex, and alloys: Ideal for manufacturing high-strength and durable components.

Diversity in machining processes

We focus on providing solutions that fit the needs of each client. For this, in our machining company in Bilbao, we apply various working methodologies, guaranteeing precision and quality in each piece.

Variety of finishes and solutions

We adapt to the needs of our customers, whether for production in short series or large volume productions. We can customize the finishes according to the requirements of each industrial application.

Advice on part design

We offer a comprehensive parts design and optimization service, ensuring that each component fulfills its function efficiently. We take care of the manufacture under plan facilitated or we can design from scratch according to the needs of the customer.

Our featured projects

At Asimer Group, we have worked on high-level projects for industries such as petrochemical, naval, oil & gas, desalination, and water treatment. Below, we highlight some of our most significant achievements.

Share your project with us and we’ll make it happen.

Share your project with us and we’ll make it happen.

Engineering developments

Asimer Group specializes in project management (PM), quality assurance (QA), and engineering through the integration of different manufacturing technologies.

Welding and overlay

The Welding Department at Asimer Group is divided into two main functions: casting repairs that require specific solutions, and special overlay applications.